Henry Snaith and Zhiping Wang comment on the effects of temperature on perovskite structures. For more comprehensive information on this problem, you can check out their paper ‘Bandgap-Tunable Cesium Lead Halide Perovskites with High Thermal Stability for Efficient Solar Cells’ in Advanced Energy Materials.

What causes the thermal instability of perovskite materials?

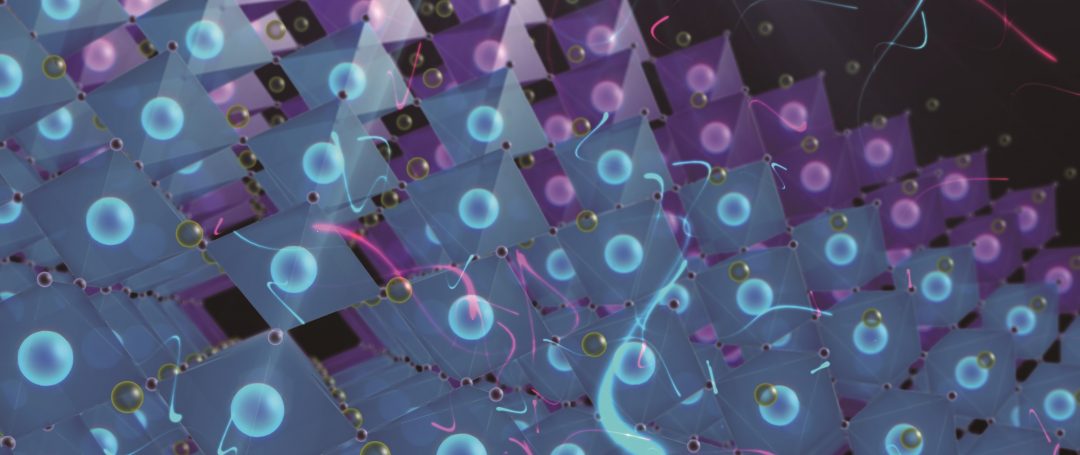

The best working metal halide perovskite compounds are “hybrid”, which means they contain organic and inorganic ions. The organic ions, and specifically the ammonium halide salts, are relatively volatile in comparison to the metal halide components. For example, the archetypal methylammonium (MA)-based perovskite solar cells (that is, methylammonium lead triiodide: MAPbI3) exhibit an intrinsic thermal instability due to the relatively volatile MA cations, which are released from the film during heating, and this process would be accelerated in the presence of moisture. In addition, poor film morphology – for instance small crystalline grains and a high density of surface defects – appears to make this thermal instability worse. This can be visualized by considering that, under temperature, the perovskite surface “unzips” at defect sites.

Moreover, in actual devices, perovskite materials are in contact with interlayers/electrodes, which might induce/accelerate thermal degradation of the perovskite layer. For example, the organic hole-conductor spiro-OMeTAD, well-known as an efficient hole-transporting material, tends to crystallise at elevated temperature (85 °C), resulting in pinholes through which the top electrode materials can invade and interact with the perovskite layer, causing decomposition. Furthermore, other materials used as charge extraction layers have been found to react directly with the perovskite, for example the electron transporter zinc oxide, which decomposes the methylammonium.

What strategies are being applied to make perovskite-based devices more thermally stable?

The first strategy relates to changing the perovskite composition. Methylammonium has really been identified as the weakest link, so moving away from this to a slightly less reactive organic ammonium cation, formamidinium (FA), has resulted in considerable improvements (Energy Environ. Sci. 2016, DOI: 10.1039/C3EE43822H). Attempts to move to a completely inorganic perovskite, such as CsPbI3, have shown some promise but have thus far failed to convincingly deliver a material with crystallographic phase stability. Using mixtures of FA with Cs at the A-cation site have shown some of the best results for improving the thermal stability (Science 2016, DOI: 10.1126/science.aad5845). Other approaches include tuning dimensionality (Nat. Energy 2017, DOI: 10.1038/nenergy.2017.135), which enables the use of larger, more thermally stable organic cations, since they no long have to fit within a 3D crystal structure.

The second strategy relates to improving the crystallinity of the films. This can be achieved via engineering the crystallization process, which has been shown to enhance the thermal stability of perovskite films, by i) controlling the structure/purity of complexes and colloids in perovskite precursor solutions, ii) tailoring nucleation sites in perovskite intermediate phases, and iii) adding impurity ions/additives to gain pinhole-free, large-grain perovskite films with less grain boundaries/defects.

Thirdly, post-treatment of fully-crystallized perovskite films to passivate defects (i.e., bulk defects, grain boundaries, and surface vacancies; Science 2018, DOI: 10.1126/science.aap9282) would improve thermal stability. Fourthly, to prevent/mitigate interlayer-induced thermal degradation of the perovskite layer in complete devices, organic materials with a high Tg, inorganic materials (CuSCN, oxides, or carbon-based materials), or a combination of the two can be adopted as charge transport layers (Science 2017, DOI: 10.1126/science.aam5655). In the case of interlayer materials that require doping, thermally stable interlayer doping techniques are also necessary (Adv. Mater. 2017, DOI: 10.1002/adma.201604186).

Last but not least, robust encapsulation techniques would greatly improve the thermal stability of perovskite-based devices, partially due to the prevention of oxygen and moisture infiltrating into perovskite materials, but also by inhibiting the escape of volatile decomposition products from them.

How close are we to solving this issue?

Through continuous efforts by the whole community over the past few years – including the above-mentioned strategies – the thermal stability of perovskite materials and perovskite-based devices has been largely improved. Oxford PV has claimed that their perovskite PV cells pass the international electrotechnical commission (IEC) thermal stressing and thermal cycling standards for terrestrial PV, including the 85/85 damp/heat aging test, which is very encouraging and suggests that there already exist solutions which can suffice for standard module level glass–glass laminate encapsulation; however, when combining with other stressing factors – for example, continuous light soaking and electric biasing – the rate of thermally induced degradation may accelerate. It would also be preferable if the technology could survive failures in module-level encapsulation, which will require non-encapsulated cells being able to survive the typical 1000 hours that thermal stressing modules are required to surpass. We also consider that one potential future deployment of perovskite PV could be in flexible modules. In this scenario, the level of encapsulation may not be as robust as for ridged glass-based modules. Therefore, further effort is required for these alternative applications.

Interested in more on perovskites? Some of the top perovskite researchers are sharing their thoughts: