Researchers at the Jiangxi Science & Technology Normal University have fabricated poly(3,4-ethylenedithiathiophene-co-3,4-ethylenedioxythiophene)/poly(styrene sulfonate) (poly(EDTT-co-EDOT)/PSS) and poly(3,4-ethylenedithiathiophene-co-2′-hydroxymethyl-3,4-ethylenedioxythiophene)/poly(styrene sulfonate) (poly(EDTT-co-EDOT-MeOH)/PSS) copolymer thin films with high electrical conductivity at 298 K.

PEDTT is one of the most extensively studied analogues of the widely used conducting polymer PEDOT. PEDTT has unique electrical properties and also has potential to be used in, for example, rechargeable batteries and photovoltaic devices. However, many techniques used to homopolymerise EDTT give powders which are difficult to form into thin films. Jingkun Xu and colleagues report in the Journal of Applied Polymer Science the chemical oxidative copolymerisation of monomer mixtures in poly(styrene sulfonic acid) aqueous solutions. This produces colloidal dispersions which can easily be processed to create free-standing films. Earlier work by the team showed that this method can be used to fabricate PEDTT/PSS films but these have the disadvantages of relatively low conductivity and poor thermoelectric properties.

PEDTT is one of the most extensively studied analogues of the widely used conducting polymer PEDOT. PEDTT has unique electrical properties and also has potential to be used in, for example, rechargeable batteries and photovoltaic devices. However, many techniques used to homopolymerise EDTT give powders which are difficult to form into thin films. Jingkun Xu and colleagues report in the Journal of Applied Polymer Science the chemical oxidative copolymerisation of monomer mixtures in poly(styrene sulfonic acid) aqueous solutions. This produces colloidal dispersions which can easily be processed to create free-standing films. Earlier work by the team showed that this method can be used to fabricate PEDTT/PSS films but these have the disadvantages of relatively low conductivity and poor thermoelectric properties.

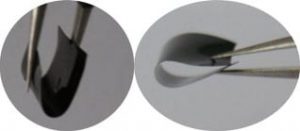

The ideas behind the new study included the known preparation of other EDOT-based copolymers, and the fact that EDOT-MeOH is more soluble in aqueous solutions and is more easily electropolymerised than EDOT. The process gives conducting, thin and flexible polymer films which can be easily cut. The conductivity of both poly(EDTT-co-EDOT)/PSS andpoly(EDTT-co-EDOT-MeOH)/PSS films is higher than PEDTT/PSS. Moreover, adding dimethyl sulfoxide (DMSO) or DMSO/isopropanol (IPA) to the polymer dispersions organically doped the films and led to an increase in electrical conductivity for the co-polymer films, in contrast to PEDTT/PSS. At the same time, this had little influence or improved on the Seebeck coefficients.

The ability to fabricate flexible PEDTT-based films with good electrical and thermoelectrical properties in the presence of a watersoluble polyelectrolyte is encouraging in terms of improving current devices and increasing the number of applications using PEDTT.