IBM’s discovery of a new class of industrial polymers with a range of tunable and desirable properties provides a new opportunity for research and development to both academia and materials manufacturers. Two related classes of materials have been discovered which possess a very distinctive range of properties that include high stiffness, solvent resistance, the ability to heal themselves once a crack is introduced and to be used as a resin for filled composite materials to further bolster their strength.

“Although there has been significant work in high-performance materials, today’s engineered polymers still lack several fundamental attributes. New materials innovation is critical to addressing major global challenges, developing new products and emerging disruptive technologies,” said James Hedrick, Advanced Organic Materials Scientist, IBM Research. “We’re now able to predict how molecules will respond to chemical reactions and build new polymer structures with significant guidance from computation that facilitates accelerated materials discovery. This is unique to IBM and allows us to address the complex needs of advanced materials for applications in transportation, microelectronic or advanced manufacturing.”

IBM scientists used a novel ‘computational chemistry’ hybrid approach to accelerate the materials discovery process that couples lab experimentation with the use of high-performance computing to model new polymer forming reactions. They applied the unconventional method together with collaborators including UC Berkeley, Eindhoven University of Technology and King Abdulaziz City for Science and Technology (KACST), Saudi Arabia.

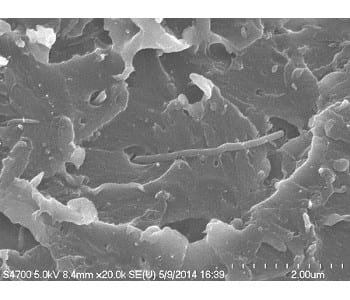

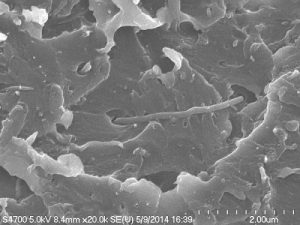

One polymer remain intact when it is exposed to basic water, but selectively decomposes when exposed to very acidic water. Under the right conditions, it can be reverted back to its starting materials, which enables it to be reused. The material can also be manufactured to have even higher strength if carbon nanotubes or other reinforcing fillers are mixed into the polymer and are heated to high temperatures (see figure).

At low temperatures, another type of polymer can be formed into elastic gels that are still stronger than most polymers, but still maintains its flexibility because of solvent that is trapped within the network, stretching like a rubber band.

A remarkable characteristic of these gels is that if they are severed and the pieces are placed back in proximity so they physically touch, the chemical bonds are reformed between the pieces, making it a single unit again within seconds. This type of polymer is called a “self healing” polymer because of its ability to do this and is made possible here due to hydrogen-bonding interactions in the hemiaminal polymer network.