Mitsubishi Materials introduced a new insert grade for steel turning under the name MC6015. The new ISO series of chemical vapor deposition (CVD) coated inserts have been developed with Mitsubishi’s patented nano-texture coating technology. This technology delivers exceptional wear and edge chipping resistance, for machining at the high performance parameters required in todays’ metal cutting world.

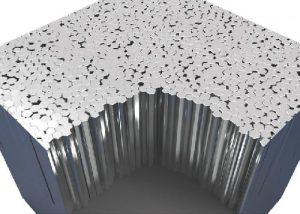

The nano-texture coating operation optimises the crystal growth to tightly compact the crystals into a uniform structure. Source: Mitsubishi Materials

The unique new nano-texture coating operation optimises the crystal growth to tightly compact the crystals into a uniform structure that prevents edge failure and prolongs tool life. This Al2O3 ultra thick layer makes MC6015 ideal for continuous machining of steel, especially when conducting high speed, high feed machining that generates extreme surface temperatures. This new patented layer is coated with a smooth and hard wearing surface that prevents abnormal damage and weld chipping.

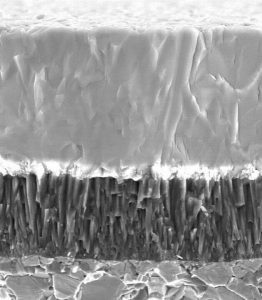

Below the smooth surface and nano-texture layer, Mitsubishi has introduced its new TOUGH-Grip Technology layer and is the second of two patented technologies that are included in the new insert grade. The Technology is an interface between the insert layers that is controlled at the nano-level. According to the Japanese company, benefit of this technology is that it allows the grip layer to provide an extreme bonding to prevent delamination of the various layers.

From bottom to top: Ultra thick layer Al2O3 delivers wear resistance even at high temperature, TOUGH-Grip (white color) prevents delamination of the coating, nano-texture provides wear and chipping resistance. Source: Mitsubishi Materials

MC6015 has a gold coloured Ti compound top-face layer to deliver good heat and wear resistance. This Ti compound also helps to eliminate crater wear on the Al2O3 layer, which makes the new grade suitable for high speed machining. Whilst this combats the onset of crater wear, the tool maker has also coated the flank surfaces with a smooth layer that prevents abnormal wear and chipping. When integrated with the microscopic TiCN coating, the smooth layer delivers improved surface finishes and consistent tool life.

The MC6015 insert grade is available with a vast array of chipbreaker geometries to provide the optimal performance parameters for light, medium and heavy cutting applications on carbon and alloy steels. Offered in positive and negative designations with a wide variety of geometries and chip breakers for each type.