Vertical cavity surface emitting lasers (VCSELs) are a ubiquitous light emitter that has been an essential component of a wide range of technological applications in modern society, including in optical communications, data scanning and sensing, infrared illumination, and biomedical imaging, thanks to their unique performance characteristics that excel those possible with other classes of solid-state light sources, such as light-emitting diodes (LEDs) or edge-emitting lasers (EELs).

Vertical cavity surface emitting lasers (VCSELs) are a ubiquitous light emitter that has been an essential component of a wide range of technological applications in modern society, including in optical communications, data scanning and sensing, infrared illumination, and biomedical imaging, thanks to their unique performance characteristics that excel those possible with other classes of solid-state light sources, such as light-emitting diodes (LEDs) or edge-emitting lasers (EELs).

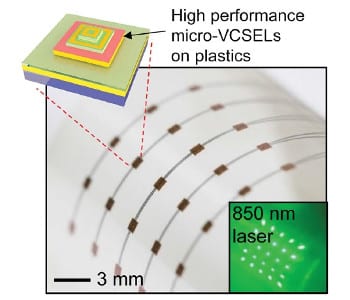

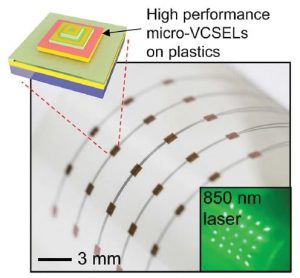

With recent rapid progress in flexible and wearable electronics, demands for coherent light sources that can operate on soft, deformable surfaces are increasingly high. In this regard, a fabrication route to enable the integration of VCSELs on various non-native substrates without the degradation of their intrinsic materials properties has been successfully demonstrated using transfer printing.

While such a novel device platform is expected to accelerate the realization of a variety of unprecedented applications, devices printed on plastics exhibit a significant reduction of performance mainly due to the inefficient heat removal arising from the low thermal conductivity of the substrate plastic and a resultant temperature increase in the active region of the VCSELs.

Researchers at the University of Southern California have now come up with a unique materials design and integration strategy that can overcome such limitations of flexible micro-VCSELs by exploiting thermally engineered heterogeneous composite assemblies, in which thin layers of metals are incorporated between the micro-VCSEL and any polymeric substrate.

These layers act as heat-spreading media, in a manner that also preserves the critical advantages of mechanically flexibility and optically transparent construction. The novel integration pathway enables a significant reduction of the effective thermal resistance of the printed device assembly, therefore dramatically enhancing its performance.

These new procedures therefore provide a realistic means to achieve high-performance coherent light sources on plastics as a new device platform for integrated flexible optoelectronics, but also is expected to be applicable to any materials system or device class that requires efficient heat management without compromising the inherent material characteristics and device performance.