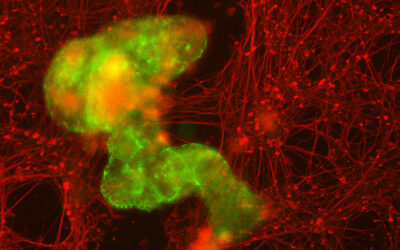

Image credit: Dr. Akhilesh Gaharwar/Texas A&M Engineering

Researchers have designed a 3D-bioprinted model of a blood vessel that mimics its state of health and disease, thus paving the way for possible cardiovascular drug advancements with better precision.

Vascular diseases such as aneurysms, peripheral artery disease, and clots inside blood vessels account for 31% of global deaths. Despite this clinical burden, cardiovascular drug advancements have slowed over the past 20 years. The decrease in cardiovascular therapeutic development is attributed to the lack of efficiency in converting possible treatments into approved methods, specifically due to the discrepancy between studies that take place outside the body compared to inside.

The team’s research aims to remodel current methodologies to minimize this gap and improve the translatability of these techniques by directing 3D bioprinting toward vascular medicine. This interdisciplinary and collaborative project was recently published in the journal Advanced Healthcare Materials.

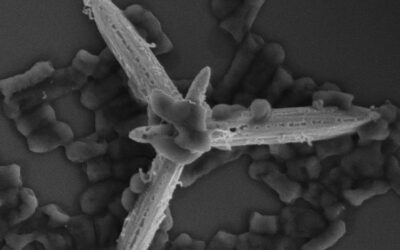

Bioprinting in 3D is an advanced manufacturing technique capable of producing unique, tissue-shaped constructs in a layer-by-layer fashion with embedded cells, making the arrangement more likely to mirror the native, multicellular makeup of vascular structures. A range of hydrogel bioinks was introduced to design these structures; however, there is a limitation in available bioinks that can mimic the vascular composition of native tissues. Current bioinks lack high printability and are unable to deposit a high density of living cells into complex 3D architectures, making them less effective.

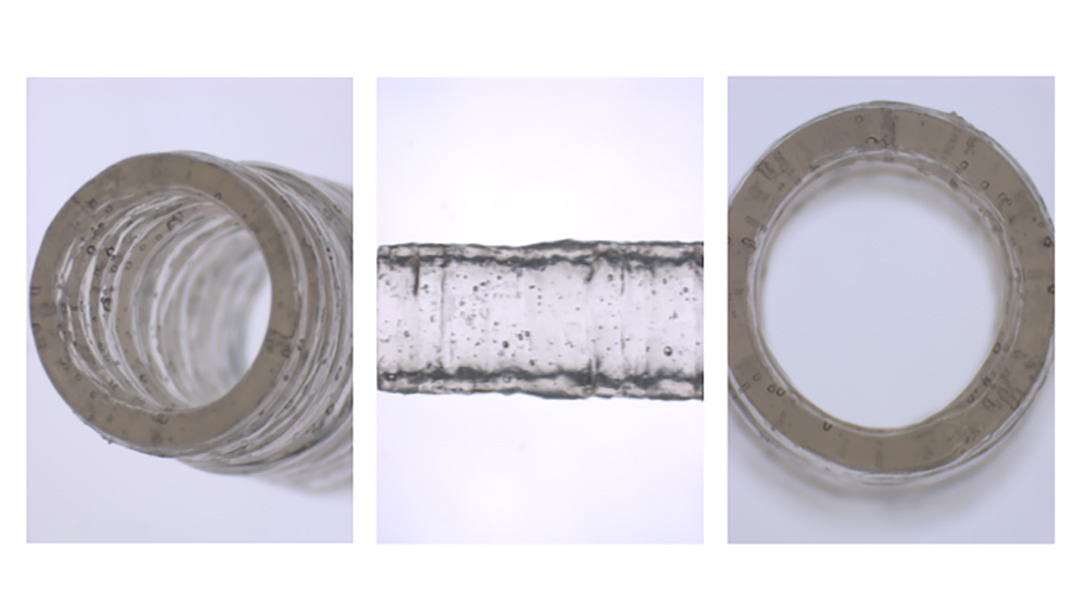

To overcome these shortcomings, Dr. Akhilesh Gaharwar and Professor Abhishek Jain of Texas A&M have developed a new nanoengineered bioink to print 3D, anatomically accurate, multicellular blood vessels. Their approach offers improved real-time resolution for both macro-structure and tissue-level micro-structure, something that currently is not possible with available bioinks.

“A remarkably unique characteristic of this nanoengineered bioink is that regardless of cell density, it demonstrates a high printability and ability to protect encapsulated cells against high shear forces in the bioprinting process,” Gaharwar said. “Remarkably, 3D-bioprinted cells maintain a healthy phenotype and remain viable for nearly one month postfabrication.”

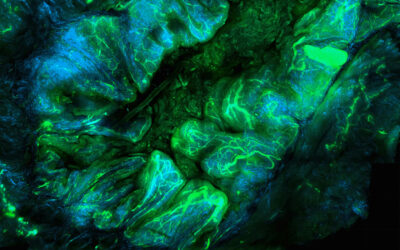

Leveraging these unique properties, the nanoengineered bioink is printed into 3D cylindrical blood vessels, consisting of living co-cultures of endothelial cells and vascular smooth muscle cells, which provides researchers the opportunity to model vascular function and disease impact.

This 3D-bioprinted vessel provides a potential tool to understand vascular disease pathophysiology and assess therapeutics, toxins, or other chemicals in preclinical trials.

Reference: Karli Gold, et al., 3D Bioprinted Multicellular Vascular Models, Advanced Healthcare Materials (2021). DOI: 10.1002/adhm.202101141