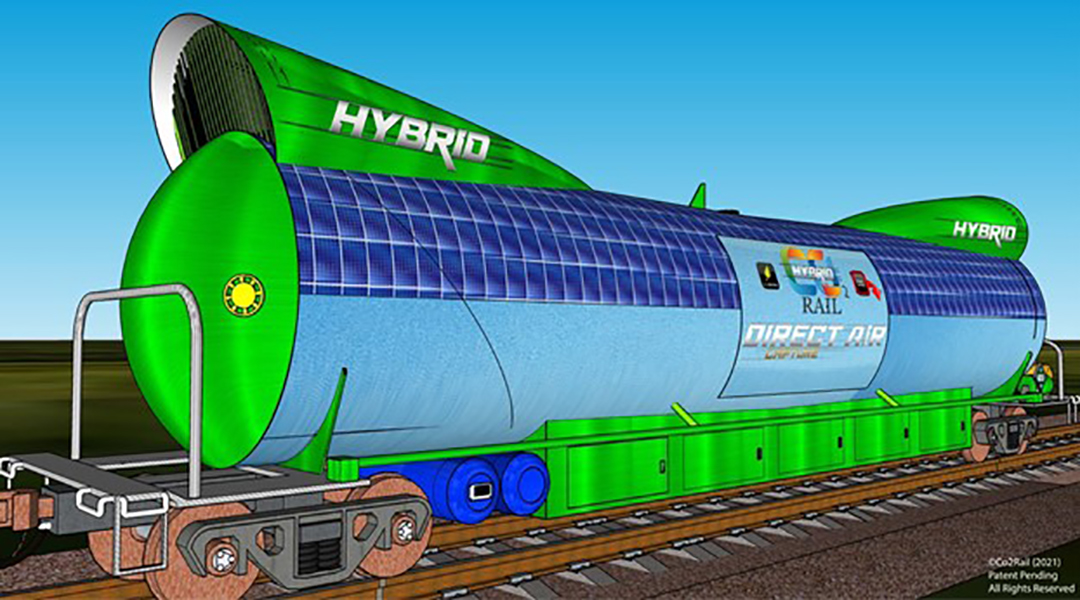

A new start-up company is looking to enhance direct air capture of carbon dioxide (CO2) using train-loaded modules to help improve airflow and therefore capture of CO2. Their systems will be attached to trains already running in regular service.

Co2Rail is using the significant amount of wasted energy produced in the dynamic braking system of freight trains to drive their direct air capture system. This unique approach can enable gigaton-scale CO2 capture in an energy efficient manner, making it affordable for downstream CO2 users to make economical use of the captured CO2.

One of the most efficient forms of large-scale, land-based transportation systems is rail. Per unit of freight, trains use roughly 90% less energy than trucks. Slowing and stopping trains, however, require a braking system that generates a substantial amount energy, much of which is lost as heat. Imagine utilizing this energy loss to put a brake on greenhouse gas emission by capturing them instead in a direct air capture system integrated into the train and operating on the fly.

There exist a number of emerging and promising ways to collect CO2 directly from air, which utilize solution and solid forms of amines, oxides and hydroxides, mineralization, and gas-adsorption methods, all requiring heat to regenerate and collect the CO2 for storage or use.

In a nutshell, the challenges facing direct air capture to reach a scale that realistically impacts global warming and fulfills the Paris agreement are eight-fold: energy, productivity, mechanical feasibility, spatial footprint, life cycle carbon emissions, economics, monetization, and scalability.

The high cost of direct air capture currently hinders its feasibility — although a recent report on learning-by-doing has been predicted to bring the cost of the technology down to $100/ton CO2. Competing technologies like the passive direct air capture system proposed by Heirloom Technologies are promising costs as low a $50/ton.

By making use of waste energy from existing infrastructure aboard trains, Co2Rail can help optimize several the above-mentioned drivers to make direct air capture a reality. It requires no external power as this is provided on-board by the regenerative braking of a slowing and stopping train. Massive volumes of air are collected by the moving train, eliminating the need for fans. As a mobile system, the equipment, land, and transportation needs of a static CO2 capture plant are removed or lessened. The CO2 emissions can be captured in a mitigation rail car. Freight and passenger trains in regular service can be deployed as the mitigation units.

The cumulative CO2 removal capacity of a global direct-air capture rail system has been projected to be gigaton scale by 2030. This mobile, direct-air capture railway technology could be integrated with self-contained CO2 utilization modules, for ‘air-to-door’ delivery of sustainable chemicals and fuels.

This is hopefully a vision that is not taking us all for a ride. Let’s hope they can deliver!

Written by: Geoffrey Ozin and Alex Tavasoli

Reference: Klaus S. Lackner and Habib Azarabadi, Buying down the Cost of Direct Air Capture, Ind. Eng. Chem. Res. (2021). DOI: 10.1021/acs.iecr.0c04839

Feature image: The dynamic braking system of freight trains can be reconfigured to enable gigaton-scale capture of CO2 directly from air. Image credit: Co2Rail