Flexible electronics have many benefits over traditional electronics which use rigid substrates. They are stretchable and flexible, allowing them to attach more naturally to test surfaces and therefore, give measurements with better signal-to-noise ratios. One example use in healthcare is flexible heat actuators that deliver focused and localized heat to destroy tissues in a procedure known as thermal ablation. These devices, which can attach on surgical tools or directly on tissues, are typically made stretchable by patterning the electrodes in serpentine or half-loop circular designs.

The problem with half-loop circular designs is that weak points occur at the sharp turnings of the loops, causing electrode break-down when stretched or under high current. Furthermore, most existing devices do not heat beyond 50°C; those that do tend to lack temperature sensing capabilities. Expanding the heating temperature range and integrating heat sensors in devices will allow surgeons to measure organ temperatures and deliver more precise amounts of heat for ablation.

Now, Paddy Chan and co-workers at the University of Hong Kong report using an Archimedean spiral design to create a flexible heat actuator-cum-temperature sensor that attaches to organs for precise temperature sensing and thermal ablation.

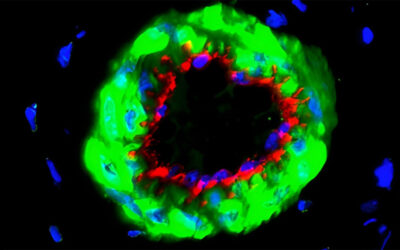

Unlike the half-loop circular design, Archimedean spiral patterns do not have weak points and their high length-to-area ratio ensures high resistance. To form the integrated actuator-sensor device, gold and chromium spirals created by photolithography were deposited on a 1.5 μm thin layer of parylene and encapsulated by another 500 nm parylene. Experiments showed the device wrapped the organ naturally, allowing the actuator to deliver enough heat to destroy the liver tissue. The device, which shows a linear sensing and heating response between 25-60°C, can burn tissues down to 2 mm deep in less than 10 min. Compared to conventional radiofrequency thermal ablation, which requires around 50 W or higher power input to reach 50°C, these flexible devices requires just 300 mW.

When one actuator-sensor device is attached on a surgical robotic hand and another on a nitrile glove, the two devices interact, allowing the glove wearer to sense the heat experienced by the robotic hand within 10 sec.

“Such a heat-sensing glove is useful because surgeons can now ‘feel’ organ temperatures via the robotic hand before and after performing thermal ablation”, says Albert Lau, the first author of the paper. This type of human-machine interaction is expected to offer a more precise way to thermally ablate tissues.

Research article available at A.H.Y. Lau, et al. Advanced Intelligent Systems, 2020, doi.org/10.1002/aisy.202000005