In nature a myriad of different fibers, such as spider-spun silks, hollow feathers of bird wings, or hierarchical veins in plant leaves are found that possess various functionalities. In particular, characteristics like their large surface area, mechanical flexibility, and feasibility to be integrated into more complex structures have triggered biomimetic design approaches to create artificial fibers at the micro- and nanoscale. These fibers are useful for a wide range of applications in materials science.

In nature a myriad of different fibers, such as spider-spun silks, hollow feathers of bird wings, or hierarchical veins in plant leaves are found that possess various functionalities. In particular, characteristics like their large surface area, mechanical flexibility, and feasibility to be integrated into more complex structures have triggered biomimetic design approaches to create artificial fibers at the micro- and nanoscale. These fibers are useful for a wide range of applications in materials science.

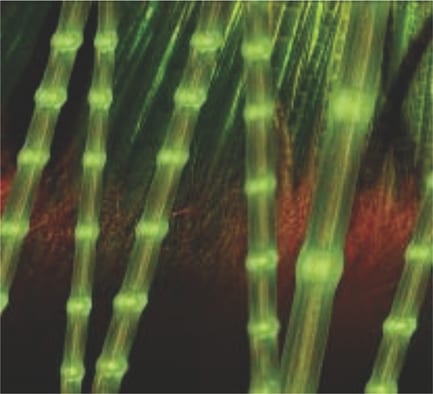

Common synthetic fabrication methods are usually limited to the generation of single component cylindrical fibers. In stark contrast, recently developed techniques reveal multicomponent fibers with flexible morphologies. Triggered by these incentives, J. Qin and co-authors propose a novel strategy for the one-step fabrication of biomimetic bamboo-like microscale hybrid fibers. In these they combine the droplet microfluidic technique with a wet-spinning process. In particular, biocompatible calcium alginate microfibers are successfully incorporated into spherical materials, such as hydrophobic microdroplets, polymer microspheres, or multicellular spheroids that are responsible for the unique bamboo-like fiber architecture. The hybrid fibers are generated by means of a specially designed droplet microfluidic device including microchannels for simultaneous oil and aqueous phase flow driven by syringe pumps. Herein, the immiscible liquids drive the formation of droplets. The process includes simultaneous droplet formation in the disperse oil phase by shearing of the continuous aqueous phase and gelation of microfibers formed by hydrophilic monomers dissolved in the aqueous phase. At the end of the output channel a spinning orifice regulates the fiber spinning process.

The main advantage of this simple and flexible technique compared to conventional methods lies in the ability to fabricate biomimetic hybrid fibers with multiple functionalities in a variety of compositions and configurations. Therefore, it is a promising approach for a wide range of applications in tissue engineering and regenerative medicine.