Paper analytical devices have found diagnostic applications in healthcare, including biomarker assays, but these “write-once/read-once” systems typically require sophisticated fabrication techniques that rely on user expertise. Enhancing the user-friendliness of point-of-care paperfluidic systems is essential in order to facilitate their use beyond the lab.

Jose Gomez-Marquez from the Massachusetts Institute of Technology, along with his co-workers, construct a library of modular, low-cost, and reusable paperfluidic blocks that do not require any additional instrumentation, called Ampli.

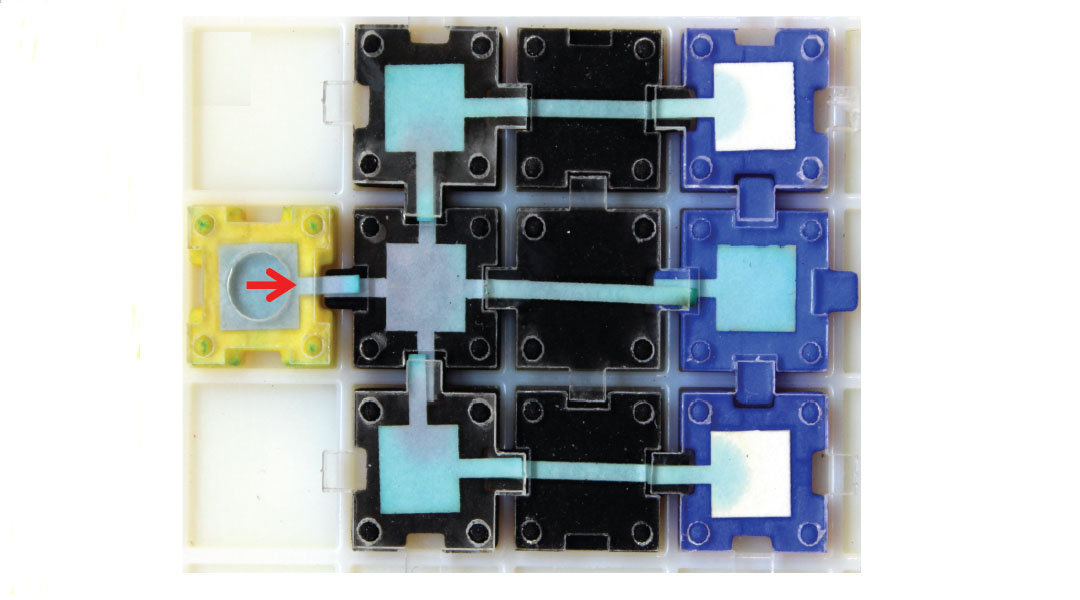

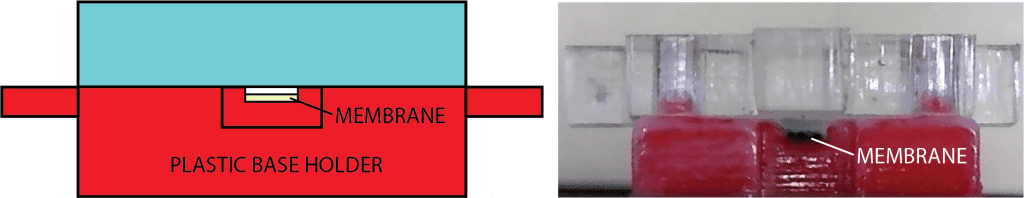

The blocks were designed in CAD and then 3D printed in a plastic casing containing paperfluidic membranes. The membranes are composed of paper or cellulose, nitrocellulose, glass fiber, or other materials, depending on the block function: transport blocks (TB), connection blocks (XB), sample pads (SP), absorbent pad blocks (AP), nitrocellulose carrier blocks (NC), and conjugate pad (CP) blocks. Colored dyes were added to provide a visual indication of successful interconnection. The blocks are also compatible with third-party parts, making the system “Design for Hack” friendly.

Cross-section of Ampli block assembly.

When these Lego-like blocks are connected in a particular array, they form a paperfluidic circuit. To demonstrate the performance of the block assembly, a multiplexed, functional lateral flow immunoassay (LFI) was constructed and tested for the detection of a cancer marker.

To find out more about this novel approach to paper-based analytical devices, please visit the Advanced Healthcare Materials homepage.