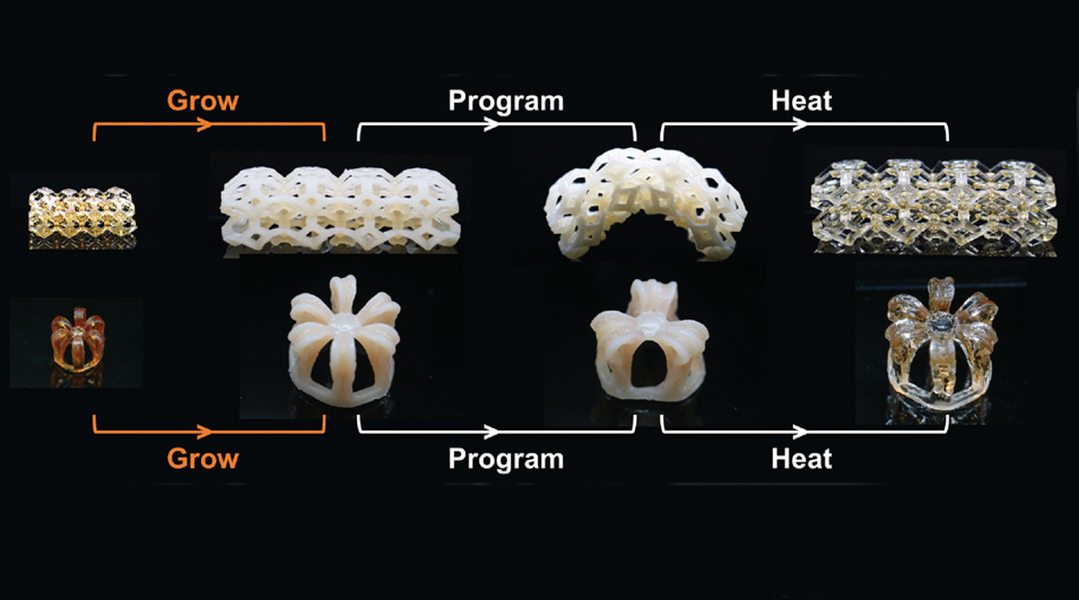

4D printing produces a living polymer network that can be printed into 3D shapes and then broken down into its monomer units for reuse.

4D printing produces a living polymer network that can be printed into 3D shapes and then broken down into its monomer units for reuse.

4D printing of metallic shape-morphing systems can be applied in many fields, including aerospace, smart manufacturing, naval equipment, and biomedical engineering.

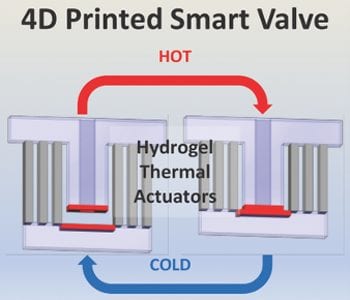

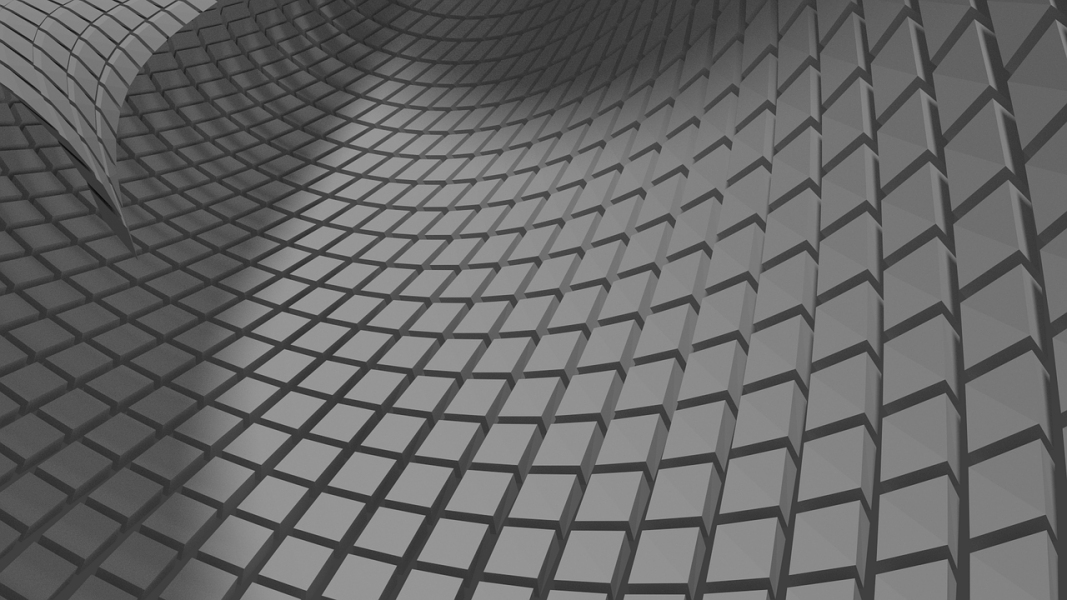

Novel 4D printing produces a Sydney Opera House-like 3D structure.

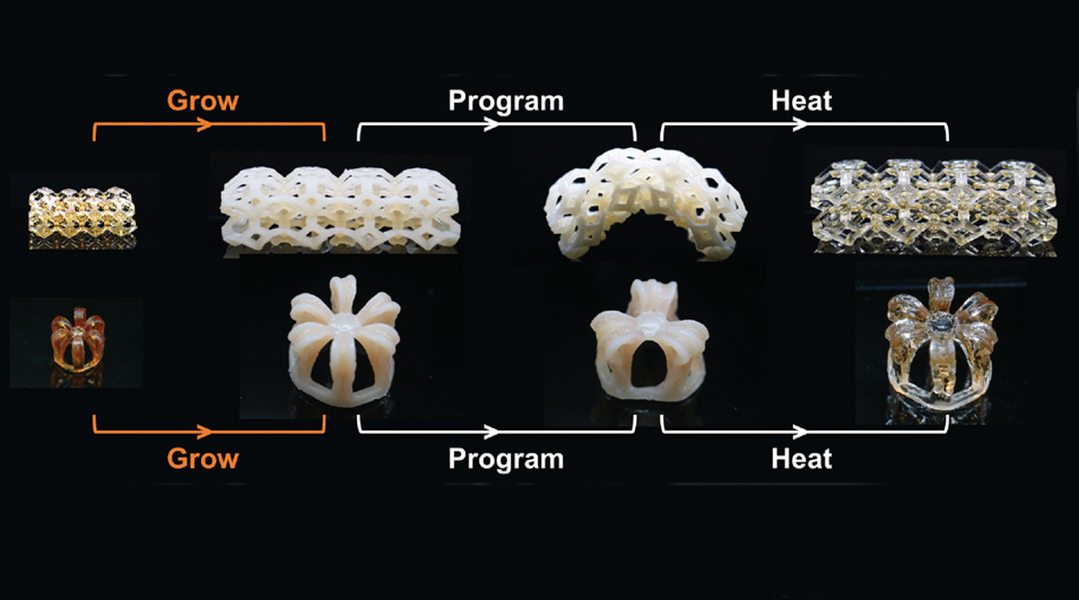

Australian researchers report on a 4D-printed thermally active hydrogel valve, which can control the flow of water.

The art of 4D bioprinting is creating multiresponsive smart architectures for nerve regeneration.

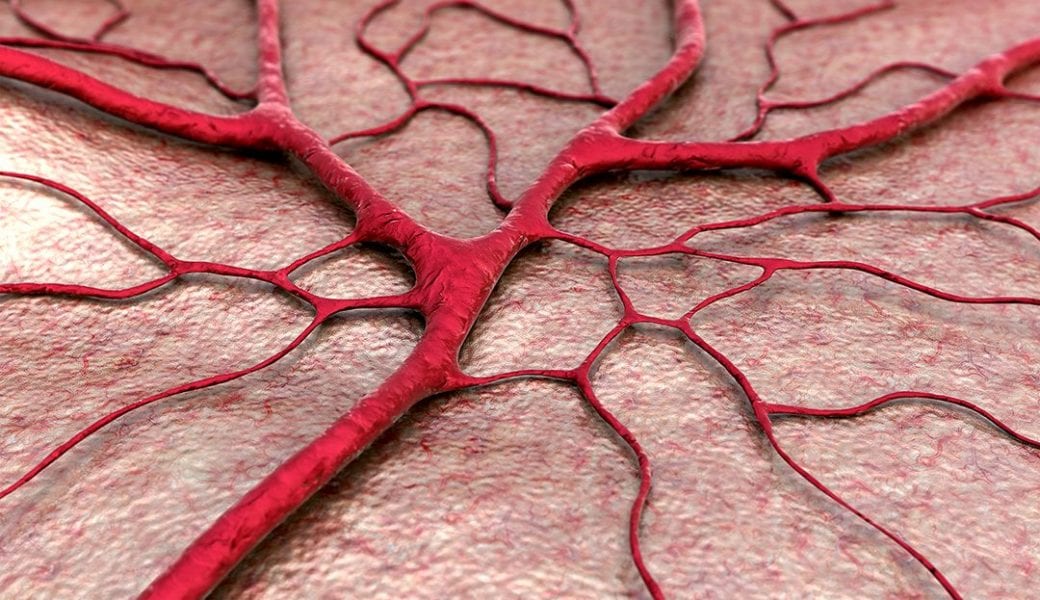

An advanced 4D bioprinting approach uses shape-morphing, biopolymer hydrogels to form the basis for blood vessels and other tubular structures in artificial tissues and organs.

Taking inspiration from nature, scientists create a two-component catapult that overcomes limitations in 4D printing.

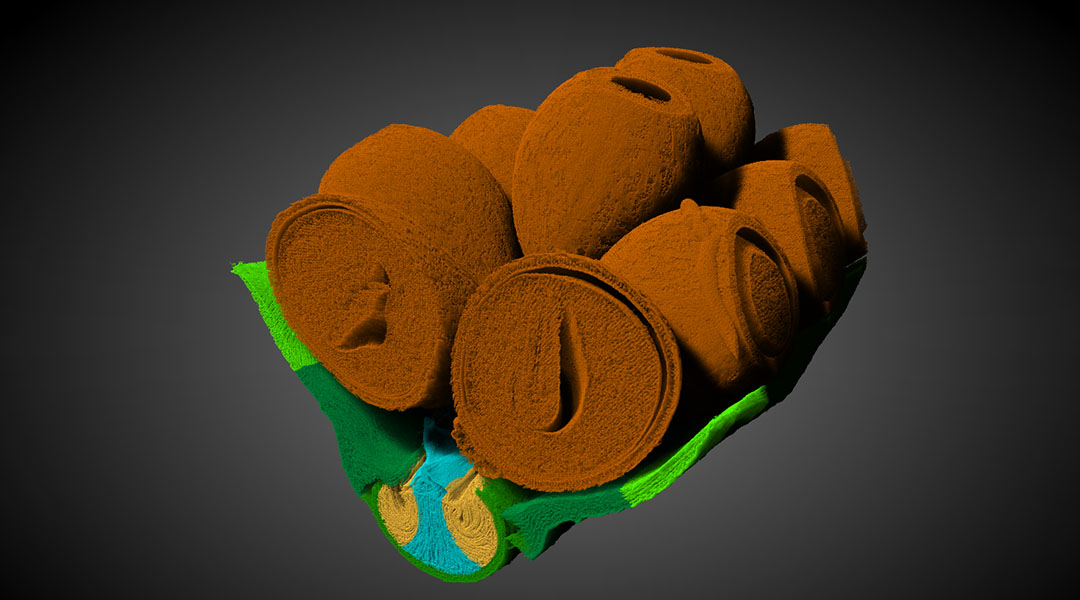

Precision micromanufacturing of electrospun microfibers can create 3D scaffold structures which support the growth of tessellated microtissues.

Formation, formulation and applications of micro- and nanoparticles for 2D and 3D printing.

2016 Printing for Fabrication Conference to address advancements in print-based Ffabrication, functional materials, and applications on September 12-16, 2016, at the University of Manchester.