Tissue engineering aims to recreate biological function by habituating one or more types of human cells to a supporting scaffold construct with appropriate biological, physical and mechanical properties. Recent progress with adaptive manufacturing processes, including 3D, 4D printing, and optical patterning, support the vision of synthetically prepared, cell-instructive material systems that mimic many of the structural aspects of biological tissues.

To date, this vision has been restrained from realization by technological tradeoffs between the level of exerted architectural control and the requirement for specialized, typically biologically incompatible materials.

In their research published in Advanced Materials, Joerg Lahann and his colleagues at the Biointerfaces Institute, University of Michigan, USA, report a key technological progress that has the potential to catapult electrospinning into the pole-position among adaptive manufacturing technologies for 3D tissue engineering.

In contrast to conventional electrospinning, the new method enables precise patterning of electrospun polymer fibers into scalable, 3D scaffolds. That solution-based electrospinning has yielded 3D architectures of high precision with high reproducibility. Moreover, the process is compatible with the typical polymers used for tissue engineering, such as PLGA.

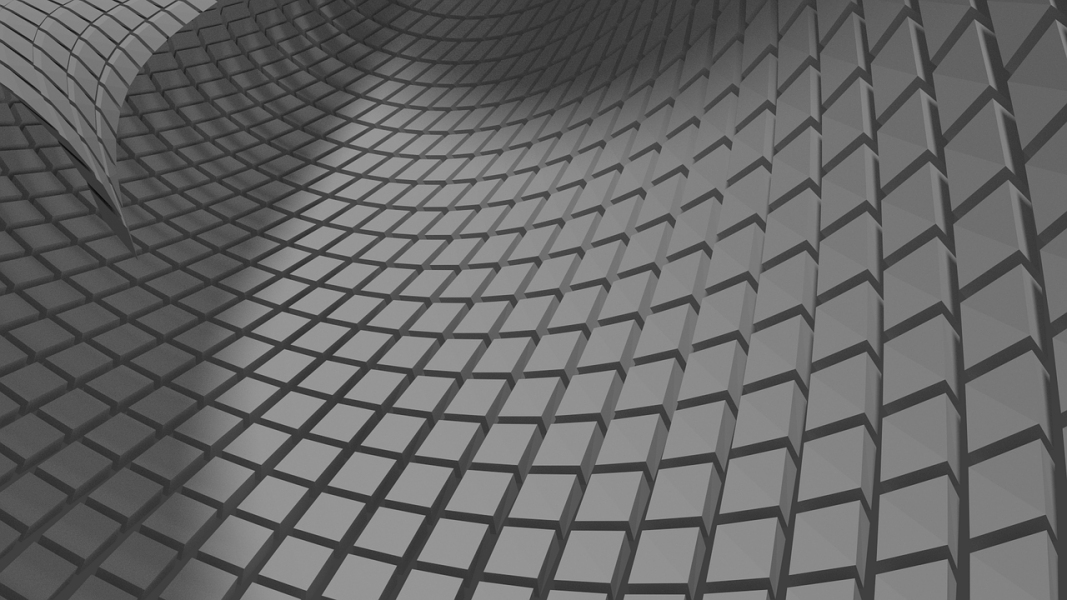

This novel technology, termed 3D jet writing, enables manufacturing of scaffolds according to user-defined specifications of the shape and size of both the pores and the overall geometric footprint. For example, honeycomb-like structures were prepared that are mechanically robust and easily handled despite the low relative density of 4% material by volume. The remaining open areas are readily infiltrated by cells in a 3D culture distinct from other cell culture or tissue engineering techniques.

To demonstrate the utility of this technology, human mesenchymal stem cells were cultured on the fabricated scaffolds and were differentiated towards an osteogenic lineage. Subsequently, their ability to heal a critical bond defect in mice was evaluated.

As another proof-of-concept, the authors demonstrate the effectiveness of tessellated bone scaffolds to selectively attract metastatic cancer cells, highlighting their potential as versatile models for bone metastasis.