Whilst modern medicine has long moved on from the frightful days of strong liquor and something to bite down on as a substitute for anesthetic, there is still one aspect of visits to the doctor that fills many people the world over with dread: hypodermic needles.

Now, an international team of engineers led by Rutgers University in New Jersey may be helping to consign such fears to the sharps waste bin of history.

Reporting in Advanced Functional Materials, Howon Lee and his team at Rutgers, along with Giuseppe Barillaro and colleagues at the University of Pisa, have developed a 4D-printed microneedle device that takes inspiration from nature to help better adhere to skin in a simple and pain-free way.

A microneedle is, as the name suggests, a needle on the micrometer scale. The advantages of microneedles is that their size means they are less invasive, less painful, and easier to use than normal needles for drug administration, and they are not new; they have been growing in development over the past couple of decades now.

What makes Lee and Barillaro’s device novel however is it is 3D printed into an easily programmable shape, which then changes its shape to something more desired upon drying. This is known as a smart material, and it is this latter property that describes the microneedle as “4D”, rather than 3D-printed.

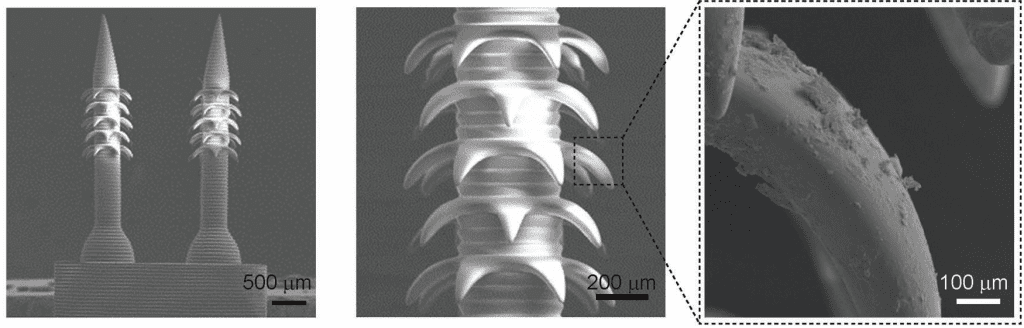

Looking at “microneedles” found in nature, such as hooks from certain parasites, the printed microneedle has backwards facing barbs to allow for better skin adhesion, as one of the drawbacks of other microneedles is being able to remain in the skin. This is particularly important if the microneedle is being used for sustained drug release over a period of time, requiring the need for it to remain in place.

“We think our 4D-printed microneedle array will allow for more robust and sustained use of minimally invasive, pain-free and easy-to-use microneedles for delivering drugs, healing wounds, biosensing and other soft tissue applications,” said Lee for a press release by his university.

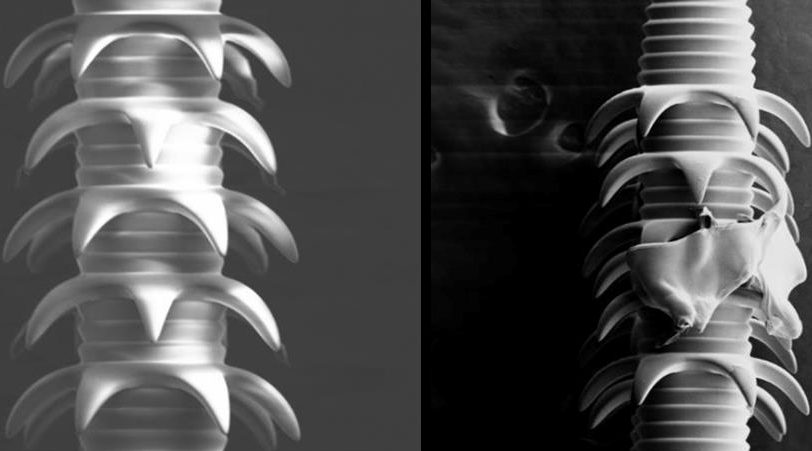

The barbed structures are difficult to 3D print, and so the original structure of the barbs are 3D printed to horizontally stick out of the needle. A post-printing process of rinsing and drying causes these straight structures to naturally bend into the barbs shown in the image above.

To test their barbed microneedle, the researchers used it on raw chicken breast to find the adhesion strength to tissue is 18 times stronger than barbless microneedles. A video made by the research team has been uploaded to YouTube highlighted this unique property (not for the squeamish).

Furthermore, the desired barb properties — such as thickness and curvature — could be tailored depending on the material composition of the printing solution, and level of exposure to UV light during printing.

The authors believe that their 4D-printed, bio-inspired microneedle array has great potential for robust and sustained soft tissue applications, such as transdermal drug delivery, tissue wound healing, and long‐term in vivo drug delivery and biosensing.

Full paper found at: Daehoon Han et al., Advanced Functional Materials, doi.org/10.1002/adfm.201909197