Micro-fibers as well as nano-fibers and their non-woven mats have many applications in biomedicine, tissue engineering, and other material sciences. In particular, synthetic polymer fibers on the micro- and nano-scale attract much interest as cell scaffoldings and matrix composites.

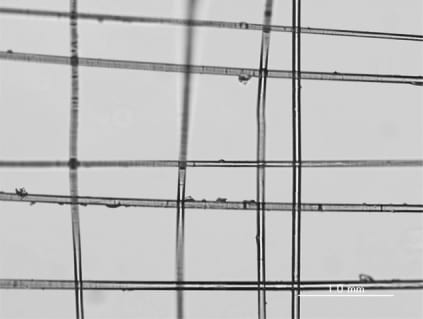

Usually these mats are made by electrospinning. The arrangement, density, and diameter of the fibers, however, cannot be appropriately controlled. Nanostructures produced by weaving or knitting fabrics are ideal, since the woven structure increases the strength and flexibility, and the pore size and uniformity can be controlled. Unfortunately, conventional weaving technology causes mechanical failure of the micro and nano-filaments.

Recently, Dr. Hong Xia and Prof. Toshihiro Hirai from the Shinshu University in Nagano, Japan, demonstrated a nano-weaving concept based on voltage-induced actuation forces. In previous work, they found that some synthetic polymer fibers have electroactive characteristics. The fibers were actuated and showed different behaviors under applied electric stimulation. In their paper Xia and Hirai examined several polyvinyl alcohol (PVA) micro-fibers to confirm the actuation effects, and proposed a promising nano-weaving technology principle.

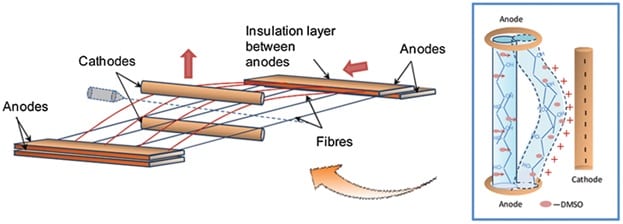

Based on the electroactuation behavior of fibers, the Japanese scientists designed a shedding motion. The shedding motion is the most significant aspect of the weaving process. It determines the order of the required number of warp threads to be lifted or lowered for weft threads to pass and form a fabric pattern.

Based on the electroactuation behavior of fibers, the Japanese scientists designed a shedding motion. The shedding motion is the most significant aspect of the weaving process. It determines the order of the required number of warp threads to be lifted or lowered for weft threads to pass and form a fabric pattern.

Although, the PVA fibers have be optimized for micro- and nano-weaving, the investigations show the possibility of a new micro-weaving and nano-weaving process using electroactuation forces. According to Xia and Hirai, main advantage of this electroactuation weaving technology is that ultra thin and uniform textiles can be fabricated from micro- and nano-fibers. This method can also be applied to other micro- or nano-fibers, for various applications, e.g., in biomedical and tissue engineering.