Biomedical devices from implants to prosthetics are normally in contact with the human body for long periods of time and must be biocompatible. However, transitioning new biomedical materials, such as hydrogels, from the lab to the clinic can be economically unfeasible due to rigorous toxicity testing and characterization.

In their progress report in Advanced Materials, Liam Grover and co-workers from the University of Birmingham and the University of Huddersfield discuss how clinically approved hydrogels can be structured in new and different ways to generate materials with a variety of new physical properties.

Prof. Liam. M. Grover: “Hydrogels are water-based gels comprised of large, organic molecules, with similarity to a lot of the molecules that you find in the body. Hydrogels have been used widely to study how cells can respond to their local environments, and have also been used to synthesize delivery systems for therapeutics or as scaffolds for tissue engineering.

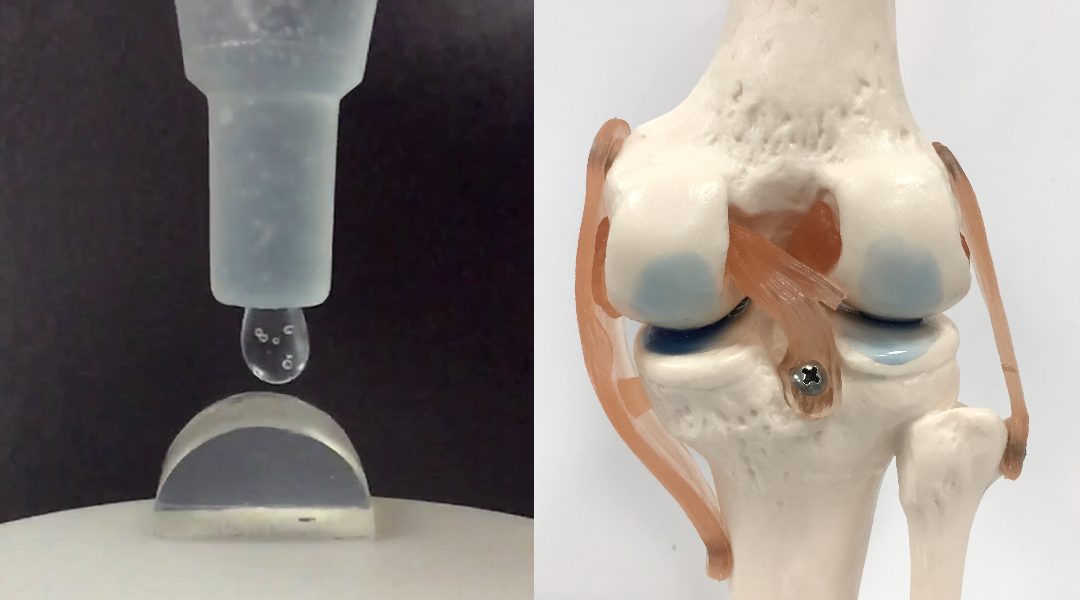

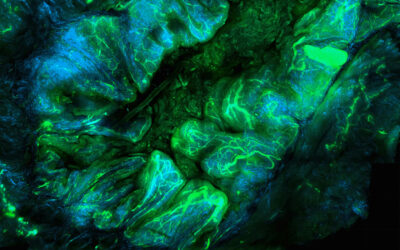

The structures of hydrogels can be tailored to provide a diverse range of properties. For example, microgel suspensions known as “fluid” or “sheared” gels have the ability to self-structure post-shearing—a particularly interesting property for biomedical applications. When shear is applied to the gel, it liquefies and can be combined with a biological fluid, which then thicken or solidify in situ. In this way, we have developed materials for the repair and regeneration of cartilage, skin, and the cornea, that can be delivered using different clinical applicators, including cannulas, needles, sprays, and eyedroppers.

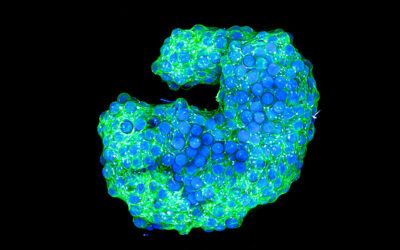

We are also exploiting the self-healing properties of these materials to enable the development of new 3D bioprinting processes. We can extrude a second material into the fluid-gel, which is then supported in all directions during the gelation process. This provides the opportunity for layer-by-layer construction of hydrogel structures or interfacing of two mechanically dissimilar materials.

These systems are far from optimal and need considerable refinement before finding widespread use across medical fields. Current methods for sterilization can cause significant breakdown or structural changes to the gel. Gentler sterilization methods, such as the use of alternative light sources, like UV and blue light, would be advisable. We should also continue to explore the potential of these materials for delivering complex, composite structures.”

To find out more about the structuring of hydrogels across multiple length scales for biomedical applications, please visit the Advanced Materials homepage.