Water purification and filtration are key steps in a range of industrial processes. The properties of the membranes used for this task depend on the specific type of filtration required.

Oftentimes, the development and testing of a new membrane for filtration can be a slow and laborious task, but recent work from an American team of scientists seeks to streamline this process.

Atomic layer deposition (ALD) is a technique that is common in the semiconductor industry. It employs gasses to make very thin layers on the surface of a membrane.

The properties of the gas determine the behavior of the new membrane, allowing researchers to easily tune their new membranes to meet the requirements of their system.

“ALD, in principle, is great,” said Seth Darling, a co-author of the study and director of Argonne’s Advanced Materials for Energy-Water Systems (AMEWS) Energy Frontier Research Center. “The challenge is that most polymers that are used to make membranes are not amenable to coating with ALD.”

Until now, the gasses used for ALD were unable to stick to the surface of the membranes used for water purification. The team found that dipping membranes in a tannic acid bath, gave the membranes a surface that could bind to ALD gasses.

“There’s a whole library of things you can do with ALD. This technique now opens up that library for polymer membranes.” — Seth Darling, director of Argonne’s Advanced Materials for Energy-Water Systems Energy Frontier Research Center

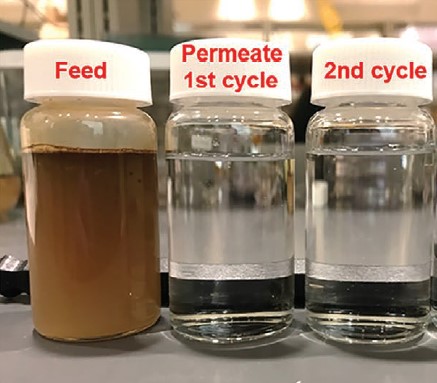

The team demonstrated proof of concept by trailing an ALD fabricated membrane in an oil and water separation test (see above). The membrane was able to maintain good performance after many cycles of filtration and mechanical deformation.

With this proof of concept in hand, the team is also developing the tools for scaling up ALD so that it can be used for industrial applications. “We currently use lab-scale reactors for these research studies, but we are building tools for efficient ALD processing of large area substrates. This will allow pilot-scale testing of our ALD materials,” said Jeffrey Elam, a senior chemist at Argonne and study co-author.

This simple pre-treatment process, has opened the door to a breadth of new possibilities in water purification.

Reference: X. Yang et al. Polyphenol-Sensitized Atomic Layer Deposition for Membrane Interface Hydrophilization. Advanced Functional Materials, (2020). DOI: 10.1002/adfm.201910062

Quotes adapted from press release