Bioplastics are made from renewable plant or animal feedstock, as opposed to fossil fuels. Thus these materials are much greener than traditional plastics to boot.

Bioplastics are made from renewable plant or animal feedstock, as opposed to fossil fuels. Thus these materials are much greener than traditional plastics to boot.

Among the problems they present, which have so far hindered their widespread application in consumer products, are their poor mechanical properties. Often, if the bioplastic is flexible it is not tough, if it is tough it does not have high impact strength, and so on. You get the picture of materials that cannot be used, for example, to make your garden plastic lunch box, as they would not last long.

One of the most promising starting materials to make bioplastics is cellulose, which is the most abundant renewable polymer in the world. The team of Yukihiro Kiuchi at the Smart Energy Research Laboratories of NEC Corporation in Japan, has been working for some time in improving cellulose bioplastics by adding cardanol, to achieve for example high water resistance, traditionally the Achilles’ heel of cellulose bioplastics. It is important to note that both cellulose and cardanol can be derived from nonedible plants (or anyway nonedible plant biproducts), thus not competing with food sources.

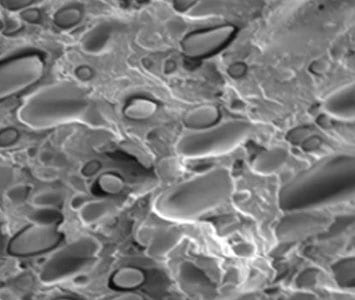

Even though cardanol-grafted cellulose has many useful properties, it lacks the combination of high-impact strength and high flexibility that is necessary for durable consumer products. To achieve this, Kiuichi and coworkers added a tiny amount of a traditional petroleum-derived plastic material such as polyethylene (the material that makes the bulk of supermarket plastic bags) or polypropylene (found in reusable plastic containers, such as many Rubbermaid products). The amount of petroleum products they add is only 5%, which means the other 95% of the material is a bioplastic and thus renewable. The final material has both high impact strength (so you can smash stuff onto it several times before it breaks) and high flexibility (it bends but it does not break easily). This new type of plastic has all it needs to succeed in a complex marketplace, including the price. Even if the authors do not mention it in their article, all the starting materials used here are off-the-shelf ingredients, and thus the process should be scalable for industrial production.