Matter can exist as a gas, liquid, or solid. Without confinement, only solid materials maintain a specific shape, making them particularly interesting for functional materials. Nanoparticle surfactants, however, can invoke specific shapes on liquids—harnessing this property would enable the shaping of liquids by a simple molding process.

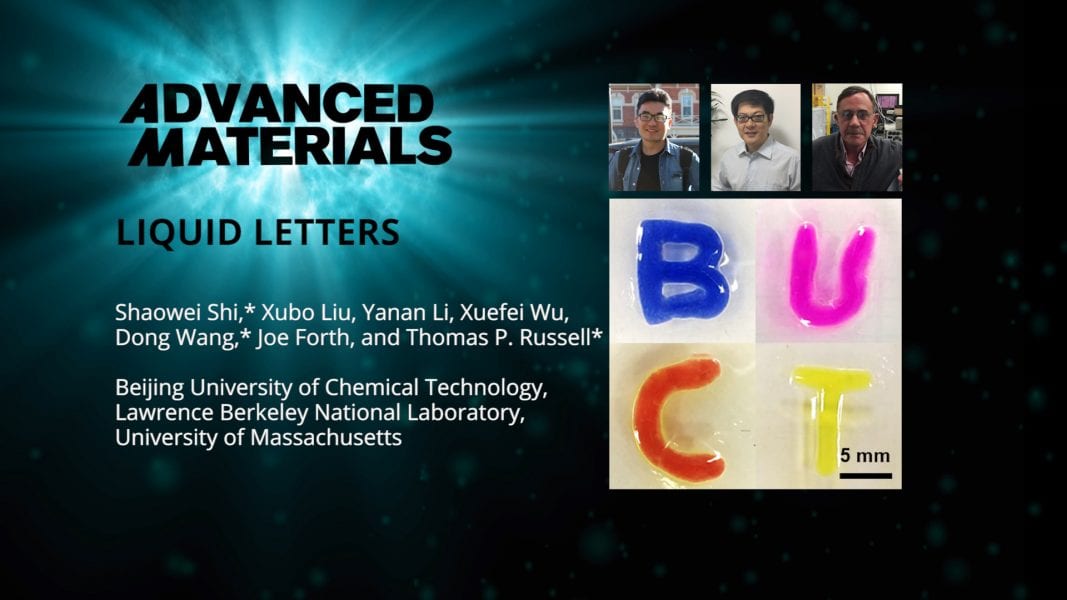

In their communication in Advanced Materials, Shaowei Shi and Dong Wang from the Beijing University of Chemical Technology; Thomas Russell from the University of Massachusetts, Amherst, the Lawrence Berkley National Laboratory, and the Beijing University of Chemical Technology; and co-workers use interfacial jamming of cellulose nanocrystal (CNC) surfactants to structure liquids that maintain the shape and details of their mold with high fidelity.

First, the mold is pre-wetted with a carbon tetrachloride (CCl4) solution containing amine-terminated poly(styrene) ligands, to which an immiscible aqueous CNC solution is added. The CNCs and ligands assemble into nanoparticle surfactants at the oil–water interface. Immersing the mold into a solution of amine-terminated poly(styrene) in CCl4 causes complete CNC encapsulation of the liquid phase, which rises from the mold due to its lower density. The concomitant decrease of interfacial area jams the CNCs, thereby locking in the molded shape of the aqueous phase.

Independent pendant drop tensiometry of the liquids used in the study reveals a rapid coverage of the interface between the liquids with the nanoparticle surfactants that varies with pH, providing critical insight for setting the molding conditions. The molded liquid retains the shape and details of the mold with high fidelity after release into the CCl4 solution. Extensive manipulation can be endured for pH values of 1.2 or less; this means both flowable liquids and viscous gels can be used for the all-liquid molding. The shape of the molded liquids can be changed and even erased simply by increasing the pH.

To find out more about this all-liquid molding approach for next-generation soft materials, please visit the Advanced Materials homepage.