Carbon fiber-reinforced carbon has outstanding material properties and many applications but is extremely expensive - how to improve the processing of this useful material?

Carbon fiber-reinforced carbon (C/C) is a composite material consisting of carbon fiber reinforcement in a matrix of graphite. The material is dedicated to very high-performance and high-cost applications, mainly in the domain of aerospace technology. C/C composites are most widely known as the material for the nose cone and wing leading edges of the Space Shuttle. Furthermore, they are used as plasma-facing components in Tokamak reactors (fusion technology). As carbon-carbon brake discs and pads they are a standard component of Formula One and aircraft brake systems. C/C is well-suited to structural applications at high temperatures, or where thermal shock resistance or a low coefficient of thermal expansion is needed.

Since the fabrication processes and the high-temperature tests are extremely expensive, optimization in terms of processing routes and the prediction of their behavior in use may enlarge the scope of application. Thus, intense modeling efforts have been performed in these directions.

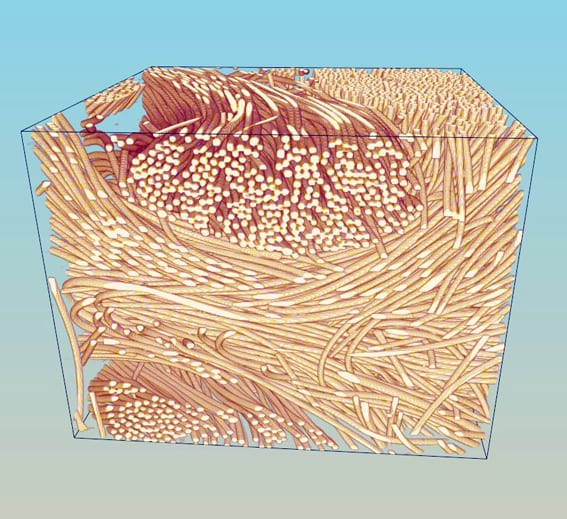

To get a sound description of the composite morphology X-ray computed microtomography (CMT) is a beneficial tool, because of its exceptional capacity for the acquisition of large, accurate 3D images of the material structure. Now, in new work, scientists of the University of Bordeaux 1 Science and Technology give an overview of the present state of research. They show efforts made in the characterization of C/C composites as a tool for modeling their lifecycle.

The comprehensive review describes the methods to gain information about the various stages of the material life: 1. material fabrication, when the carbon matrix is progressively inserted in the arrangement of carbon fibers; 2. the finished product to evaluate its properties; 3. use in a harsh environment to evaluate degradation. The presented studies involve image processing and pattern recognition, morphological analysis, and direct numerical simulation of reaction/diffusion systems with moving boundaries.

The overview reveal that the assessment of geometrical and transport properties throughout the material evolution is possible on the basis of phase-contrast CMT images. An incorporation of the structure-property relationships in large-scale models of processes and degradation tests are crucial and are still going on.