Transparent, flexible and thin coatings capable of blocking oxygen are highly desirable for applications such as plastic food packaging and protection of flexible electronics. Thin metal and ceramic coatings can block oxygen, but tend to have problems with adhesion, cracking, and environmental-friendliness. For example, thin aluminum layers on polyester, typically found in snack foods packaging, have been linked to a variety of health problems due to leaching of the metal into groundwater.

In their recent paper published in Macromolecular Rapid Communications, Jaime Grunlan and co-workers (Texas A&M University, USA) have demonstrated a process to apply a super gas barrier to plastic packaging films using only polymers in a water-based solution. This new technology allows them to quickly fabricate thin oxygen blocking layers in a single step, without the problems associated with metal or ceramic barrier layers.

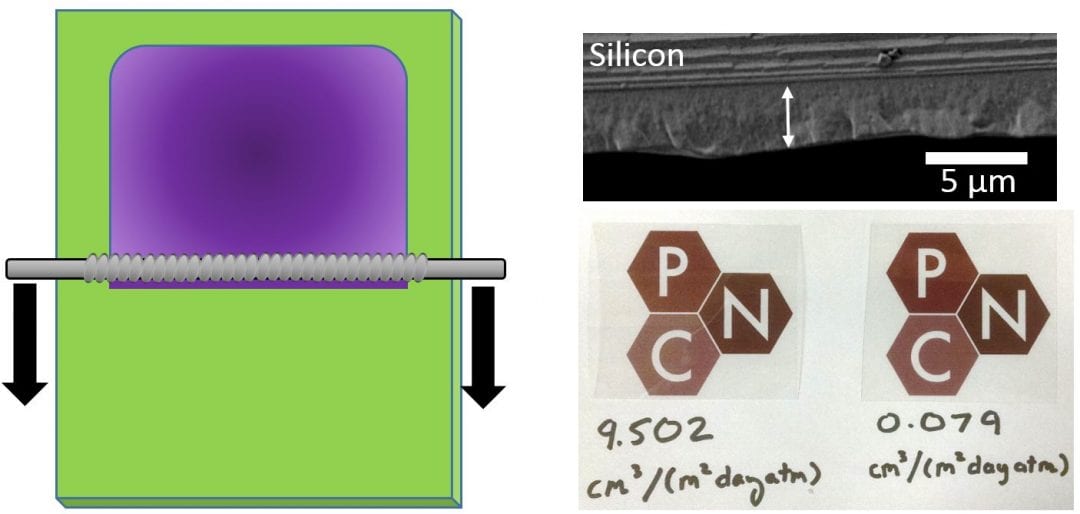

Two oppositely charged polymers (i.e., polyelectrolytes) are combined in a single water-based solution. Under the appropriate pH conditions, the two polymers will strongly associate with each other after coating the solution onto a plastic film. The association between these polymers is so strong that even a small gas molecule like oxygen cannot get through the film very easily. A 2 µm thick coating reduces the oxygen transmission rate of a 0.127 mm polyester packaging film by a factor of more than 100. This means food packaged with these coated films could be preserved for much longer, thus reducing spoilage/waste. The films are fabricated under ambient conditions using low-cost, water-based solutions, providing a tremendous opportunity for single-step deposition of polymeric high barrier thin films. This coating system is a useful industrial opportunity for a variety of packaging applications. The environmentally-benign process, with very few processing steps, offers the opportunity for scalable, low cost barrier films.