by Nusret Sena Güldal (Universität Erlangen-Nürnberg)

A new study from Prof. Seema Agarwal and her colleagues from University of Bayreuth, Germany, shows that mechanical properties of Bombyx mori silk fibroin can be tuned by coupling it with another biocompatible polymer for further implementation in tissue engineering. Remarkably hybrid fibers can be processed without affecting the surface morphology of silk fibroin, the new study argues.

Recently, there is an increasing number of areas in biomedical science in which silk fibers are exploited, as a result of their biocompatibility, biodegradability, mechanical properties and elasticity. These properties of silk fibers are especially useful for regenerative medicine. In terms of mechanical strength, silk fibers offer an interesting combination of toughness and ductility, which makes these fibers very attractive for load-bearing tissue engineering like bone regeneration. Nevertheless, scaffolds engineered from silk fibers do not possess the same mechanical properties; hence they are weak and brittle.

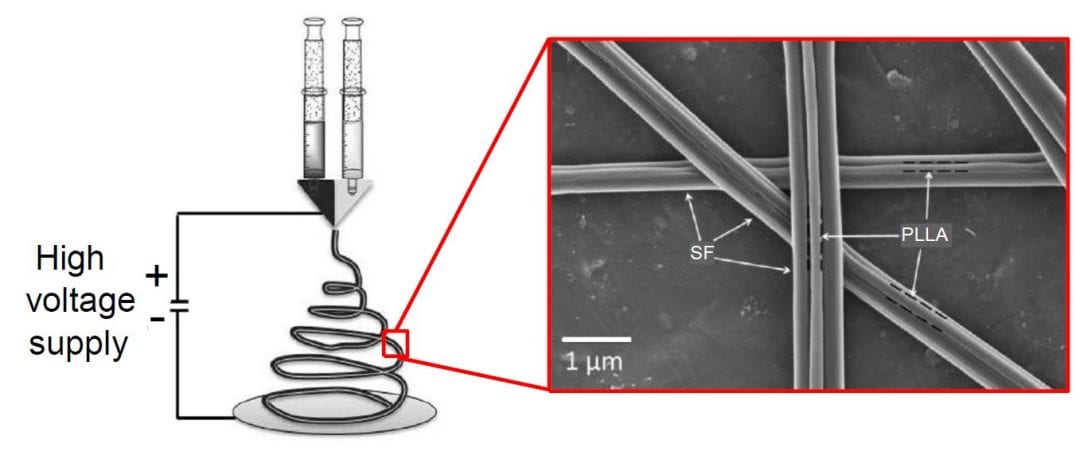

In their paper “Two-in-One Composite Fibers with Side-by-Side Arrangement of Silk Fibroin and Poly(ʟ-Lactide) by Electrospinning”, Prof. Agarwal and her colleagues succeeded to produce hybrid fibers in side-by-side arrangement via electrospinning, which is a well-known and robust method for fiber production. By electrospinning silk fibroin (SF) together with poly(ʟ-lactide) (PLLA) to produce hybrid fibers and subjecting these hybrid fibers to a post-treatment procedure of 80°C annealing under methanol atmosphere, Agarwal and her colleagues demonstrated that the hybrid fibers carry more than double the strength of pure silk fibers: hybrid fibers exhibited a breaking strength of around 16.5 MPa, while pristine silk fibers were in the range of 7.19 MPa.

Yet, “the challenge is to get defect-free side-by-side morphology along the fiber,” said Prof. Agarwal. Excellent biomaterial properties of silk fibroin originate from its secondary structure. The precise control of size, distribution, orientation and arrangement of non-crystalline and crystalline domains and the chain conformation in nanometer scale is necessary for the required cell activity on the surface, for elasticity, mechanical strength and for biodegradation. Hence, post-treatment methods are utilized to manipulate fiber morphology for specific applications. “The fiber morphology of each component should not be influenced by each other during post-treatment.” Prof. Agarwal added.

By studying the morphology of the hybrid fibers, it was confirmed that silk fibroin and poly(ʟ-lactide) sides of two-in-one fibers retained their individual secondary morphologies after the post-treatment, with silk fibroin side maintaining a β-sheet structure and poly(ʟ-lactide) side providing high crystallinity.

“These two-in-one hybrid fibers are yet to be tested for regenerative medicine purposes” Prof. Agarwal said. “Such fibers, however, have a promising future in many different applications, such as scaffolds for tissue co-culture by utilizing surface properties of individual sides and dual-release drug delivery systems.”

We would like to thank all participants in the Macromolecular Journals Writing Competition.

We would like to thank all participants in the Macromolecular Journals Writing Competition.

The best contributions are now featured on MaterialsViews and will go into the draw for the iPad mini. The winner will be drawn at the Macromolecular Colloquium, February 2016 in Freiburg and will be informed by email.

We hope you enjoy reading the news articles from our young talents.