Due to waste build up in the environment, researchers are looking at substitutes for packaging materials using biodegradable polymers. Biodegradable polymers have been developed, but starch can be used as a cost-effective alternative.

In their work reported in the Journal of Applied Polymer Science, Viviane Machado Azevedo and colleagues experimented with improving the existing properties of starch by adding sodium montmorillonite (MMT) clay nanoparticles to strengthen blends of corn starch and whey protein (WPI). The purpose of this experiment is to improve the optical and mechanical properties of starch.

Thermoplastic starch (TPS), a homogenous melt generated from the destructurization of starch, is sensitive to moisture and has reduced mechanical properties relative to synthetic plastics. To improve TPS, WPI, which is a biodegradable material, is added due to its mechanical strength.

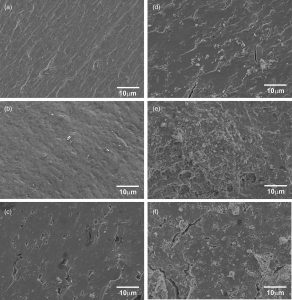

SEM micrographs of nanocomposites.

WPI is still at a disadvantage to synthetic polymers due to low moisture barrier properties. To improve this, a hydrophobic substance like a lipid should be added. Essential oils are naturally occurring lipids from plants that, in some cases, have antimicrobial and antioxidant properties, helping decrease water vapor permeability of hydrophilic polymers while improving structural, optical, and tensile properties. Rosemary (Rosmarinus officinalis. L.) essential oil possesses sturdy antimicrobial and antioxidant activity, which also aid in decreasing the water vapor permeability of WPI blends.

The addition of nanoparticles to starch and whey acts as a reinforcement that helps form nanocomposites, a polymeric material containing dispersed nanoparticles. Clay nanoparticles, such as MMT clay, has been known to be easily accessible at a low cost, as well as having strong mechanical and barrier properties.

The authors found that TPS/WPI/MMT/EO extrusion resulted in a clear green yellow nanocomposite with a potentially exfoliated structure that contains 1% of MMT. The tensile properties of the nanocomposites decreased due to the addition of rosemary essential oil, which favors interactions between polymer-oil chains and provides flexible domains within the matrix, making the nanocomposites fragile.

It is possible that the nanocomposites explored in this study could be used as active packaging materials as they can release various functional substances, which will likely slow down lipid oxidation and prevent food products from spoiling quickly. Though biodegradation studies are still required, in addition to improving food storage, these promising materials will also help tackle the growing difficulty of plastic waste buildup in the environment.