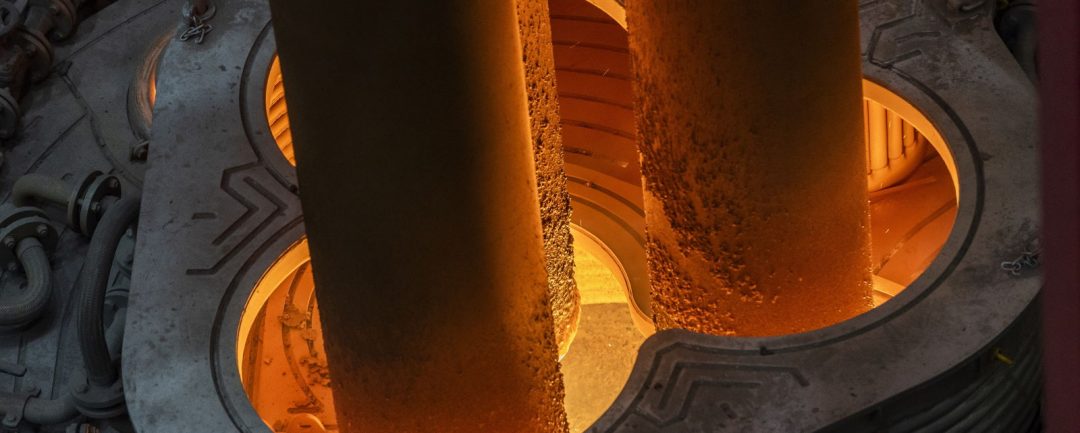

The production of steel is particularly CO2 intensive. To convert iron ore into steel, manufacturers must separate the oxygen bound in the ore from the iron using carbon, i.e. coke, to do this. In the blast furnace, oxygen forms carbon monoxide and finally carbon dioxide.

Needless to say, production, processing, and transport consume a lot of raw materials.

In contrast to all the negative news surrounding the impending climate crisis, the Science Based Targets initiative (SBTi) has recently approved the steel manufacturer, Thyssenkrupp’s, climate targets. At the same time, the organization has confirmed that the steel company is acting in line with the goals established at the 2015 Paris climate conference, where the international community agreed to limit future global warming to well below two degrees Celsius.

The SBTi is a collaboration between CDP, the United Nations Global Compact, World Resources Institute (WRI), and the World Wide Fund for Nature (WWF). Its aim is to establish science-based climate targets as standard business practice, by defining and promoting best practice in science-based target setting.

According to Thyssenkrupp, the company wants to become climate-neutral by 2050. To achieve this, the steel manufacturer has set two binding medium-term targets, which have both been validated by the SBTi: Compared with the base year 2018, emissions from production and sourced energy are to be cut by 30%, which is in line with an emission reduction pathway of “well below 2°C”. In addition, emissions from the use of products and technologies by customers are to be reduced by 16% compared with the base year 2017.

The German company aims to achieve its targets related to production and sourced energy by transforming its steel production towards direct-reduction with hydrogen, carbon capture, and using technology alongside energy efficiency measures, as well as the increased use of renewables. To reduce emissions at the customer level, Thyssenkrupp says they will focus on implement carbon capture technology, solutions for the production of green hydrogen, and the storage of renewable energy as well as e-mobility.

“Green hydrogen plays a major role in our strategy,” says Dr. Reinhold Achatz, CTO. “The production of sufficient quantities will require the expansion of renewable energies at a much faster rate in Germany than currently planned.”