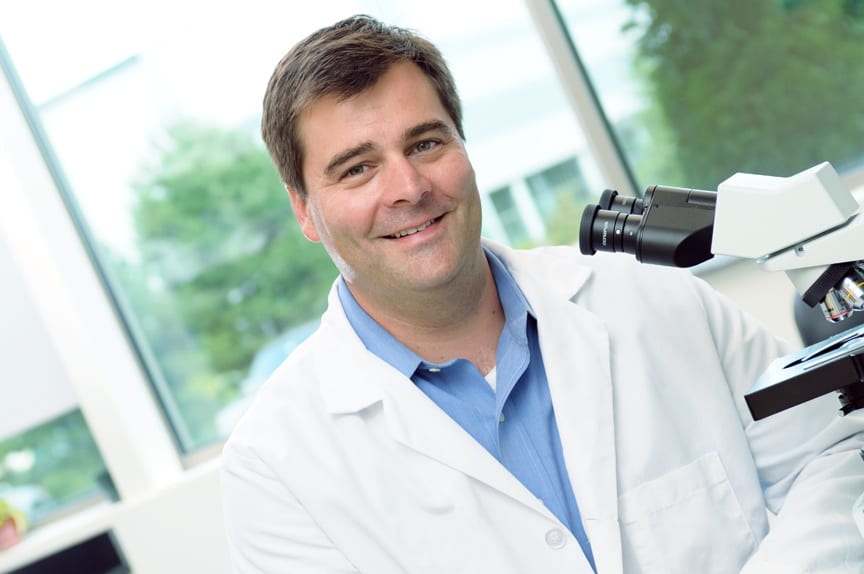

For our series on material scientists turned entrepreneurs and startup founders, we have the pleasure of talking to Jeffrey Carbeck, formerly chief technology officer at MC10, as well as former CTO at four other material science startups.

For our series on material scientists turned entrepreneurs and startup founders, we have the pleasure of talking to Jeffrey Carbeck, formerly chief technology officer at MC10, as well as former CTO at four other material science startups.

Among his numerous other roles, he is an advisor for Deloitte and the World Economic Forum for Materials Technologies, and formerly was a faculty member of Princeton University. And even before that, a postdoc with George Whitesides at Harvard. So his academic credentials go way back. He left academia in 2006.

Our chat revolves around how to start up a company based on materials science research, and how to stimulate economic growth through materials science.

[soundcloud url=”http://api.soundcloud.com/tracks/96716614″ params=”” width=” 100%” height=”166″ iframe=”true” /]

Hi Jeff.

Hi Stefano. Thanks for having the interview with me.

Sure. Thank you for chatting with us. So can you give me a brief pitch about what the main product of your most recent company is? And what is its purpose?

Yeah. So the main product of MC10 is solid-state electronics that are conformal and easily adaptable to the soft curve nature of the body. So we’ve really made wearable electronics a reality. And we’ve done that by leveraging existing semiconductor materials, like CMOS processed silicon into radical new form factors.

And your role within the company, you said was CTO. How much were you involved anyway with the business side of the company?

MC10 partnered with Reebok to commercialize CheckLight, a product that measures impacts on athletes’ heads during training

Yeah. So I was very much an outward facing member of the executive team, meaning I spent a tremendous amount of time working with our head of business development and with our CEO, both raising money, doing corporation development, and developing early stage partnerships with large companies like Reebok. So extremely involved on both the business development side, as well as putting together the corporation strategy.

And that’s really, I think, a key part of an early stage materials-enabled startup – is the materials technology and the business model and the financing strategy are also intertwined. You really need the involvement and engagement of all of your key executives in those activities early on.

So in that sense, the role that you played was very different with respect to having the same job at a large company. The division of roles is not quite so drastic, I would say.

Yeah. That’s right. You do have to fulfill your traditional role of being the most senior technical person in the community. So oftentimes, that means you have a lot of the internal R & D staff and projects reporting to you.

But, at the same time, you have to be ready to both contribute to and support significantly the commercial development side of the business. And so I think from that perspective, yeah, it’s quite different.

When did you get involved with MC10? In which stage?

So all the companies I’ve been involved with – it’s always been at the very earliest stages, where usually there is a clear market opportunity that we’ve identified, and there’s some technology that we’ve identified, and we’re putting all of the pieces together.

So actually licensing the IP. It’s better defining the business model, putting together the strategy and plan for raising the first rounds of money, and building the team.

And typically – I mean I know that every case is different. But how long does this kind of process take, in your experience?

So I’d say we’re trying to accelerate it all the time. Because I think that a lot of the companies I’ve been involved with are venture-backed. And there is a well defined timeframe at which you want to get those companies to the point where they have a significant value.

And so I would say that early startup phase takes anywhere from six months to a year. That is from when you’re really sort of just putting the concept together to when you’ve raised your first round of money – or are raising your first round of money – where you now have a fairly well defined go-to-market strategy and technology roadmap and that sort of thing.

And, of course, it continues to evolve. But I would say it’s more – it’s closer to a year. Usually it’s about six months to put everything together. And it takes a good six months, once you’ve really got a plan and an idea put together, to actually go and raise money. It’s just a long process.

Before starting your first venture, did you actually want to become an entrepreneur? Or was this kind of an accident?

Well, that’s a great question. I had been at Princeton for almost eight years, and I – couple of things. So one is I saw several of my students – undergraduates – leave and go out and start to create startups enabled by emerging technologies in chemical engineering and materials science. And I thought that was pretty impressive.

And then I started to think more about the impact that I wanted to have. And I felt like I was having impact by training people who are going out and really making a difference in the world, but I wasn’t directly engaged in translating science and invention into the market.

And I decided that’s what I really wanted to do. And so I was very fortunate. Because I had been, as you mentioned in the intro, in the laboratory of George Whitesides, where that process of commercializing technology really is a strong and dominant theme.

And so what I was able to do – I was able to reconnect with Whitesides and several people from his lab when I was there. So a venture capitalist by the name of Carmichael Roberts, who’s at North Bridge Venture Partners – he wasn’t a venture capitalist at the time. He was actually an entrepreneur that started his own company. And we started to talk about the model of commercializing university innovation, and how we might do a – how we might participate in that process that was broader than just starting a single company.

So we had this vision of starting multiple companies over time, where what we would do is start with big ideas and big needs and challenges in the market around things like healthcare and energy and consumer safety, and then start to look at technologies through a variety of different channels that we had access to, and then try and put those two together.

Which is a little bit different than saying, “Oh, here’s an interesting technology. Let’s build a company around it, and see if we can commercialize it.”

So they were not all materials science and chemistry related, basically?

Well, we knew that the technology would ultimately be materials science related. Because we wanted to build physical solutions. But we didn’t start with the technology.

So, for example, the first company we started, Arsenal Medical – the way we started that company is we said, “Well, let’s look at how medical device innovation is happening today.” And it was largely driven by mechanical engineers working directly with physicians.

And we felt like there were a couple of pieces missing there. We felt like there could be more sort of true biology, and there could also be much better materials science and surface engineering and the sort of things that we had been working on and exposed to with people like George Whitesides.

And so we put together a very broad company that said, “We’re going to do advanced materials in the context of medical devices.” We put together a really powerful founding board with Whitesides and with Bob Langer, and we went out and raised money on a very broad proposition – that we would be able to change the way medical devices were developed, using whatever materials were the most appropriate and whatever technologies were the most appropriate.

I’m not sure you could do that today. But we even started doing market assessment and looked at things like ophthalmology. We looked at cardiovascular disease, and then started to look at materials technology – both that we were developing internally, as well as ones at places like MIT and other universities, and then licensed those in over time.

What do you feel has changed since then? Why do you think that wouldn’t possible today?

I think it took a lot of early stage venture capital, when the vision and the strategy were still very broad. And we also developed an approach where we essentially built a research institute, if you will.

Oh, I see.

Because we have the ability – and the company still exists – so it has the ability to do everything from very basic synthetic chemistry and development of new monomers and modified polymers, all the way through to making devices and testing their biological responses.

The only thing we didn’t do is have our own animal facilities. We have our own pathology, our own scanning electron microscopy facility. So we could really do things very quickly, but it was a very expensive proposition.

Yeah. That’s probably something, like you said, that wouldn’t really apply today.

Right. And I think what’s much more viable today is something where much of the early stage work is done in more of a university setting, with some government funding, maybe some SBIR funding, maybe even a little bit of money from a strategic partner. And it’s much more focused before you go out and raise venture capital.

Yeah. That’s what I’ve been hearing mostly, in this series of interviews.

And I think we’re in transition. I think what we’re going to find is there are going to be some new models emerging, where I think large companies are going to be much more active, for example, in this whole process.

And I think venture capital will continue to play a role. But I think it’ll be just one of, what we call now – sort of a three-legged stool approach. You have some amount of venture capital. You have some amount of non-dilutive government money, and you have a significant amount of partnership dollars, even early on.

And that’s kind of a different model than just raising a lot of venture money, taking it a long way down the road, and then trying to sell the whole thing for significant amounts to a large company.

It’s also the fact that it takes an inordinate amount of time, I would assume, through all this money-raising.

Yeah. So raising money takes a lot of time. And then once you’ve raised the money, you actually have a fairly narrow window of time to actually get to something of value.

So one of the things we actually decided early on, when we started our company – it’s been, I think, a really important theme through all of the companies we’ve started – is that we really try and leverage existing materials and use new process technologies – and using new ways of combining and integrating and creating composites out of materials, and try and take the risk of scaling new molecules or new chemistry out of the equation. Because that can just take such a long time.

Yeah. I mean if the molecule is new, or the material is new, and the process is new, and the use is new, then it’s a risk to review, obviously.

Yeah. So, for example, with Arsenal, we decided we were going to only work with materials that had already been used in an approved medical device somewhere in the human body, and there was already FDA information and safety information about that. And it turned out that palette was still quite large.

What was inventive then was: how do you combine them into unique structures and unique products?

You mentioned many things that you’ve done during your entrepreneurship years, I would say. But what is the main change in mindset that starting your own companies has brought to you? What’s the most important thing you could have not understood, had you not participated in the founding of these companies?

Yeah. So as I went through my own academic career, and I thought about commercializing technology, the perspective was always: “What is it that I’m working on now, or that I’ve worked on in the past, that I could commercialize?”

And so the pool of ideas and technology and inventions that you’re working with, from that perspective, is fairly narrow. It’s the things that you’ve done in your own lab and in your own career.

The thing I didn’t really full appreciate is – once I stepped out of the academic world and into the entrepreneurial world, suddenly the whole universe of technology is available.

And the strength you have with your academic training is not deep knowledge of just your field, but your ability to go out and assess and understand other technologies and their potential relevance, in terms of solving problems in the market.

And that is an extremely rich vein of opportunity that I think can be further developed. And I think trying to encourage others to think about that point of view, which does not come through your academic training very much at all –

So you have to sort of discover it on your own. And I would say that, coupled with the value of being reasonably good at two things – so it’s very hard to be exceptionally good at one very specific thing and make a big impact in the world. There are only a few Tiger Woods. And that’s something –

But if you’re pretty good at two things – so if you’re pretty good at technology and you’re pretty good on the business side, that’s actually a very unique combination. And I think you can create a lot of value and actually drive things all the way to the market pretty effectively, by kind of thinking about having that dual capability.

What kind of advice would you give to someone with good ideas in materials science, chemistry, chemical engineering, who wants to commercialize them? What would you have done differently, in other words?

I would have developed an ability to assess market opportunities earlier, and really try and boost the amount of time and effort I put into truly understanding what the challenges and needs are out there in society that could be addressed by a materials technology or chemical engineering solution, and balanced that with the technical side. It’s actually not a very difficult thing to do, but it just takes some diligence, and training, and getting some information, and trying to understand not only: what’s the market size?

But what’s the potential of your solution in that market? And then how much of the value can you actually capture? In other words, who do you need to partner with to go all the way to market? And how much of the value, when you get there, can you actually capture?

Because a lot of things that look like huge opportunities at the first pass, when you actually get down to – “Well, if I’m going to provide the materials technology that enables a part of that solution” – it may not really be a very attractive business overall.

And so that’s, I think, a really important process, which I think oftentimes is done a little bit in reverse. In other words, I’ve got this material. I think it makes really cool or really interesting nanoporous membranes. What’s the market for nanoporous membranes?

I think you’ve got to sort of invert the thinking.

Yeah. You might want to provide to your customers what they want, in other words, and not what you have.

Exactly. And it oftentimes changes the way you think about how you would actually build a business.

So, for example, if you’re in the process of developing new filters for reverse osmosis, probably the business you want to be in is something that directly benefits from the energy savings that you can provide if you have, say, a high permeability, high selectivity membrane. If you just are going to go in and sell membranes or some materials to a membrane maker, that’s a tough business.

But a new kind of business model, where you capture some significant amount of the energy savings, in terms of the service that you offer, could be a tremendous business. It still needs that membrane.

It needs that membrane innovation. But what you’re actually selling to the customer is energy savings, not membranes.

Yeah. How has this changed your interaction with other scientists? Scientists typically are used to giving away things for free. I work for a journal, so I know that very well. How has this changed your interaction with them?

Well, that’s a great question. Well, a lot of people are still my friends from when I was an academia, and so I can sort of still relate to them on that level. But I think a lot of people in the materials science world and in the chemical engineering world that I know are eager to see their work become much more impactful in society, and not just within their academic circle.

And so I think I spend a lot of time now sort of coaching how to continue to pursue the development of knowledge for the betterment of society. That is the free side of knowledge development, which is what goes into our students’ minds and what goes into journal publications, but, at the same time, think about how to capture some of those ideas in an IP that can be monetized, in a way that doesn’t detract, and actually supports the more traditional academic pursuit.

Basically you already said that there is more of an appreciation from academics nowadays of what being an entrepreneur brings to their lives. But how do you think that, for example, universities or departments are then more likely to like a candidate, if he or she has an entrepreneurial background?

So I don’t know if I would say specifically it’s an entrepreneurial background. But it’s an understanding of the broader ecosphere, within which the basic research and engineering development is being done.

So, for example, I do a lot of work with startups out of MIT. I work with a lot of the faculty there. And they are, in a very impactful way, shifting a lot of the funding that’s coming into the institute away from traditional government sources.

Not to say they’re not still doing it. But there’s a huge growth now in commercial support of research, with the idea that the sponsor is ultimately going to want to have the opportunity to commercialize some of the basic discoveries.

And so it’s been interesting. Because it really changes a lot of the – so, for example, there’s a very different IP consideration when the government funds research, versus when a private company sponsors research. There are both positive and negative elements to that, I think.

A lot of the positive is there’s a much more likely pathway to commercialization. But some of the challenges are that the commercial sponsor will need to know that they have access to other pieces of intellectual property that are the university, that might otherwise end up being licensed to other companies.

So what that means, I think, for the very members who are going to be engaging in these kinds of research projects is that they just need to really be much more aware overall of the IP process. And it’s not just the way it kind of used to be, which is: you take money from the government, you write some nice papers, and then you send them over to the licensing office at the end, and they hopefully turn into patents.

It’s a more integrative process, which I think is ultimately extremely beneficial. And so I think –

Mostly because, as you said, you get much closer to the start of the invention. So you can tailor and tweak before you actually publish or you create the material. You can sort of guide the development process from the early stage towards the goal or the solution, to some kind of important product that you can commercialize at the end.

That’s right. So, for example, the MIT Energy Initiative is bringing in lots of commercial sponsors with very specific challenges that they face, that could be solved by materials and process technologies. And so as soon as you start to work on one of those problems, if you make progress against resolving it, you’ve definitely created IP.

Ideally, along the way, you’ve also developed some new science and some basic understanding and engineering capabilities that you want to describe in your publications. But it’s almost a parallel development.

Yeah. And I mean sticking to this line or thought, do you feel that it’s important for scientists at a startup company to publish in the open scientific literature?

It depends. I think that oftentimes, you want to establish and reinforce the technical credibility of the team and of the company. And so I think from that perspective, it could be very useful. I think in certain fields, it can also be very useful for getting the technology in front of a potential commercial partner.

So, for example, in the medical device arena, publishing an innovative approach to use a material or process technology to make a better medical device can get a lot of attention from the large device players, and also, I think, just give you credibility, if done properly, that you’ve got good science, as well as an interesting product.

But it’s not always beneficial. At some point in time, you’re just trying to actually finish a product, at what point –

It just becomes a distraction, I would say.

That’s exactly right. That’s exactly right. So I think there’s a time for it. It gets back to how you organize R & D. We’ve tended to have organizations where we have a small team that’s more advanced in the perspective on the technology, and trying to bring in new pieces of technology and integrate it into the perspective of the company. And that’s probably where we would do publications.

And then we have a set of teams that are focused specifically on commercializing a very well defined product, and they are much more focused on the more traditional product development.

You briefly touched on this aspect. But I’m just curious. I want to probe a little bit further. Why did you decide to ditch academia altogether, as opposed to, for example, consulting or being an advisor for the companies you founded or your cofounded?

Yeah. Another great question. I think that there are two reasons. So one is the opportunity to be an early stage technical leader in a small company is to dramatically and rapidly accelerate resource and people development.

Even today, we can still raise more money in a single round of venture capital than I could have raised in several years as a professor – and build a team much more rapidly. Of course, the objectives are much more focused.

But you can really do great engineering in a very rapid format – in a very rapid way using that kind of funding model. And I really appreciate that, having gone down the slower and more challenging process of raising money in the academic world. That’s one.

The second is these things are really only successful if there’s a core group of people who are all in. And you just need that personal and emotional and intellectual dedication by several people – not usually just one person – to actually make it real and happen.

If your senior technical person is a university professor who’s never going to leave, and is going to consult a day a week, it’s much harder to raise money than to say, “Yeah. We’ve got that guy. But we’ve also got a CTO who’s got a PhD. And he’s there every day, and this is all he’s doing.”

Sort of the whole people thing is really important to both partners and investors. And then, I guess, there’s also a personal side to it, which is – in academia, at least when I was there, it was very much an independent model, where it was the Carbeck lab, or it was the Whitesides lab.

And yeah, you collaborated. But, in the end, it was really – you were on your own, in terms of your teaching and your research and those sorts of things. Whereas in a company, it only succeeds if the team succeeds.

Yeah. Hopefully that model is kind of changing a little bit right now. I mean that would be my impression at least.

I think there’s a desire to change it. Yeah. And I think that it is changing over time. But in a traditional place, you still get tenure. And that tenure is largely determined based on your own individual contribution.

So maybe it’s post-tenure where you can then collaborate.

Now I want to sort of shift gears. As I mentioned, you’re advising Deloitte and the World Economic Forum, for example, on matters related to materials technologies. Clearly not always the fanciest lab science translates into the best business.

In your experience, how much of the great materials science research – and there’s lots of it – which has been produced around the world in the last ten years has had a tangible impact? Or is it too soon to tell?

Yeah. Again, I think the materials research that’s having a lot of impact right now – I think grew out of the nanotechnology initiative in the ‘90s. And what that really was – if you sort of step away from the controversy around what is nanotechnology and what is nano, what that really was, was a – and it was, I think, one of two really important transformations in how we think about making and shaping materials, as much as we think about what the material is going to be composed of

And so I think the other one has been and continues to be on the biotechnology/biomaterials/biorefining side of things, where we’re looking at new feed stocks for producing traditional materials through a biological route. In many ways, that has some analogies to nanotechnology, which is really about making materials or shaping materials at different length scales, but still using compositions of matter that were largely – this is not 100 percent true – but largely already available, but have unique emergent properties when you start to control things in that length scale.

And a process technology like we talked about earlier, that’s leveraging an existing composition matter, can dramatically accelerate product development, versus both a new composition and a new process. For example, I look at MC10, and if you think about the generations of technology that came from – I think it started with the soft lithographic microcontact printing technology that was being developed in the late ‘90s in the Whitesides lab.

John (note: Rogers, at University of Illinois) took it a whole ‘nother step further and said, “We can use these kinds of ideas to transfer print whole circuits off of the silicon wafers and onto substrates.” That whole development – from soft lithography to transfer printing and the design of thin conform electronics probably took about six or seven years, in terms of university technology. And it took us another three or four years for us to build into our first products with Reebok.

I think that’s been an incredibly rapid development of a new technology and a new class of materials – a new class of materials, meaning thin conform electronics that are actually composed of crucial materials.

And I think that happened in such an accelerated fashion for two reasons. One, there were academic people that actually appreciated the importance of commercializing.

But, also, it was really all process technology driven, as opposed to a new molecules and new materials driven point of view. And so I think those are the kinds of things I continue to look at and look for when I think about technologies that are likely to have a big impact commercially in the next ten years of time or less, which is what a lot of people actually care about, in terms of the commercial side.

Yeah. So, in other words, the real risk here, in the news about advanced manufacturing and as a stimulus to the economy – the role of materials science is probably that if you already had the material during the process development, it’s going to be much easier than to invent materials starting from scratch basically. That’s much better down the road. Yeah.

And I would say that the role of the materials scientist and engineer is to be much more comprehensive and open in your point of view about the materials technology. I mean the accessibility to a huge class of materials is tremendous in a way that it never was in the past, and only continues to grow.

I don’t know. There are 5,000 to 6,000 entries in the Sigma-Aldrich catalog related to materials science. You know? We sort of look at it across all those classes. And so looking at materials as an existing library or set of building blocks on which to build materials-enabled solutions, I think, is a very fruitful perspective that leads right into the whole advanced manufacturing or digital manufacturing domain.

Sort of the idea is: you’ve got a core set of multi-physics simulation models that you use to design your solution or your product. They’re tied into a materials database, like the Materials Genome Initiative that’s coming out of the Obama administration’s focus on advanced manufacturing, from which you select the materials that go into your model.

And then you use an additive manufacturing technology to build that in a very low-cost, distributed, low-waste fashion. I think that’s where things are headed in a pretty dramatic fashion.

So I mean if I asked you to pick up your crystal ball and see where the greatest possibility is for materials scientists to make contributions to economic development over the next ten years, you would say that’s mostly process engineering?

I think it’s process engineering, and I think it’s systems design, with a deep knowledge and understanding of the role and function of materials in that design. I mean the Boeing Dreamliner’s iconic of that. Right?

So the value that’s emergent – and they’ve got a pretty unique market they’re going after; they want to fly long distances in small planes that they can turn around rapidly – drove the selection of the composite materials and the process technologies, even in how to make them. And that wouldn’t have happened without deep materials science and engineering capabilities to make the system.

But the system-level design that could really leverage those materials capabilities was just as important. And so I think it’s that interplay between the systems design and the material properties and the process technology. And how those three things all work together is really where the opportunity is, I think, from a commercial perspective.

Okay. And this was our last question. I would like to thank Jeff very much, and thank all our viewers. And we’ll see you at our next installment of our series of interviews about scientists and technology in materials science.