Most metals are crystalline in nature, and are composed of ‘grains’ that are joined at the ‘grain boundaries’. It has been found that the smaller the grain size, the better the mechanical properties of the material. Hence the large-scale production of ‘ultra-fine grain’ (UFG) or ‘nano-grained’ (NG) materials is of great interest to researchers and industries. A number of industries require the materials in the form of sheets, which are manufactured using metal rolling techniques.

Most metals are crystalline in nature, and are composed of ‘grains’ that are joined at the ‘grain boundaries’. It has been found that the smaller the grain size, the better the mechanical properties of the material. Hence the large-scale production of ‘ultra-fine grain’ (UFG) or ‘nano-grained’ (NG) materials is of great interest to researchers and industries. A number of industries require the materials in the form of sheets, which are manufactured using metal rolling techniques.

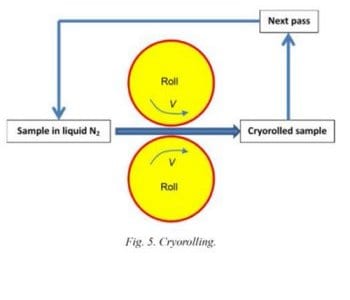

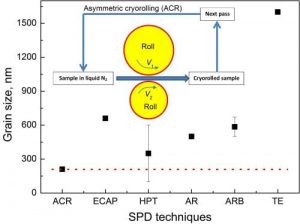

Dr Hailiang Yu and his colleagues at the University of Wollongong and the Institute of Metal Research, China, have presented a comprehensive review of the application of several advanced rolling techniques to UFG/NG materials (pure metals, alloys and composites). These advanced rolling techniques include asymmetric rolling (AR), cryorolling (CR), asymmetric cryorolling (ACR), cross accumulative roll bonding (CARB), skin-pass rolling (SPR), and a combination of other severe plastic deformation (SPD) techniques and conventional rolling techniques, such as equal channel angular press (ECAP), high pressure torsion (HPT), and accumulative roll bonding (ARB). The aim of the review is to assess the suitability of different rolling techniques to manufacture products with improved properties. The review reveals that the conditions of particular rolling techniques (such as imposing shear strain across the product thickness, rolling using different roll speeds or roll diameters, or rolling at very low or ‘cryogenic’ temperatures) play an important role in controlling the grain size, and thus improving the properties of the final product (Figure 1). This allows the application of tailored rolling techniques to manufacture products for different end applications.