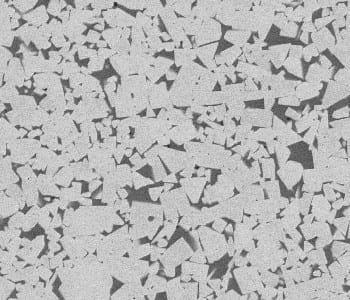

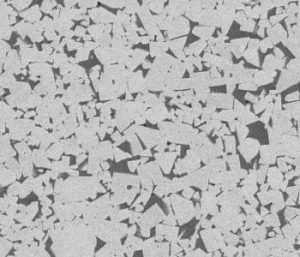

In this SEM image a sol-gel derived composite presenting WC grains (grey phase) embedded in a Fe binder matrix (dark phase) heat treated for 2 h is shown.

A method has been developed to produce crystalline fine-grained composites of basis tungsten carbide (WC)-metal starting from amorphous sol-gel masses.

The crystalline composites are prepared from amorphous sol-gel masses containing W, Fe alkoxides and extra carbon added in solid and polymeric forms. WC and Fe precipitate in-situ out of the W-C-Fe-O masses during a two steps heating process under a flux of H2/Ar up to 600-800°C and then under vacuum up to 1250°C.

The process intends to give an alternative to conventional methods for the production of WC-metal composites for small components, as i.e. the powder metallurgy route. The powder metallurgy route is limited by the quality and particle size of the initial carbide and metal powders used. The powder metallurgy route also presents limitations to produce composites with nanometric or fine grain particle size (particle size after consolidation < 0.2µm), which may be solved by using chemical routes.

The novel method offers the possibility of producing fine grain carbides embedded in a metal matrix due to the control of the in-situ precipitation kinetics, the nucleation and growth of the carbide phases in the metallic matrix.