The paradox of strength and ductility in conventional materials denotes the burden of simultaneously achieving both high strength and high ductility (HSHD). Magnesium and its alloys are considered the lightest structural alloys available on earth. Having exceptional mechanical properties makes these alloys promising for use in a very wide range of applications including in aerospace, automotive, biomedical and electronic devices.

Nevertheless, magnesium alloys generally suffer from poor formability. The production of ultrafine-grained (UFG) structures through the use of severe plastic deformation (SPD) processes is becoming of increasing interest in lightweight materials. Although SPD processing increases the mechanical strength at room temperature and resolves the ductility problem at higher temperature with the exceptional properties that UFG microstructures introduce to the material, the poor ductility at room temperature remains an unresolved problem.

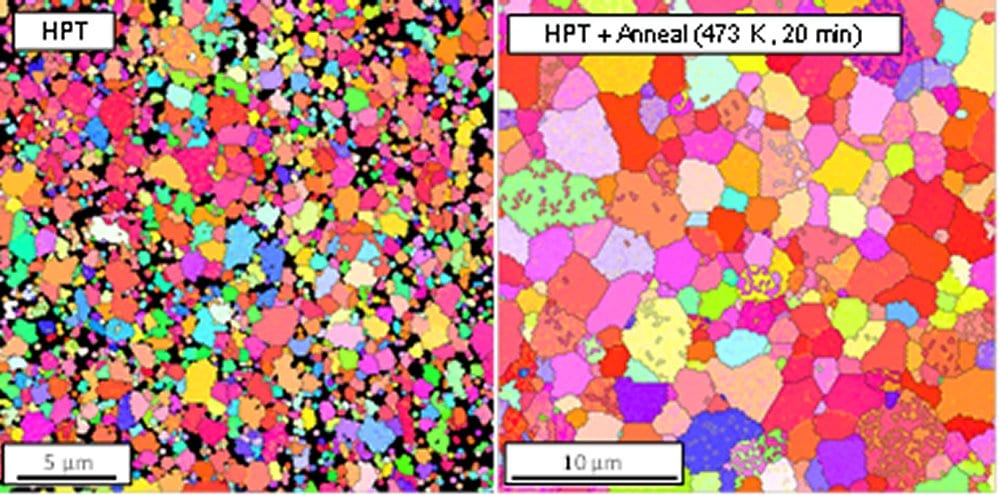

To overcome the paradox of strength and ductility, as part of their study Torbati-Sarraf et al. suggest that a post-SPD annealing for a short period of time can effectively solve the ductility problem of SPD-processed magnesium alloys. Accordingly, they examined the concept with a ZK60 magnesium alloy processed by high-pressure torsion (HPT) to obtain an HSHD material. It was found that although the grain size increases by 3 times, the grain size distribution becomes more uniform and the microstructure is significantly modified. This annealed microstructure provides reasonable ductility at room temperature for the HPT-processed material without losing the exceptional strength achieved through the very fine grain structure.