Monte Carlo (MC) methods are unquestionably among the most powerful techniques scientists and engineers use to describe the behavior of a variety of physical and chemical processes. MC methods are computational algorithms that use repeated random sampling to select an outcome among several possible events in a given process. They are most useful when the problem in question is difficult or impossible to solve using other mathematical modeling techniques.

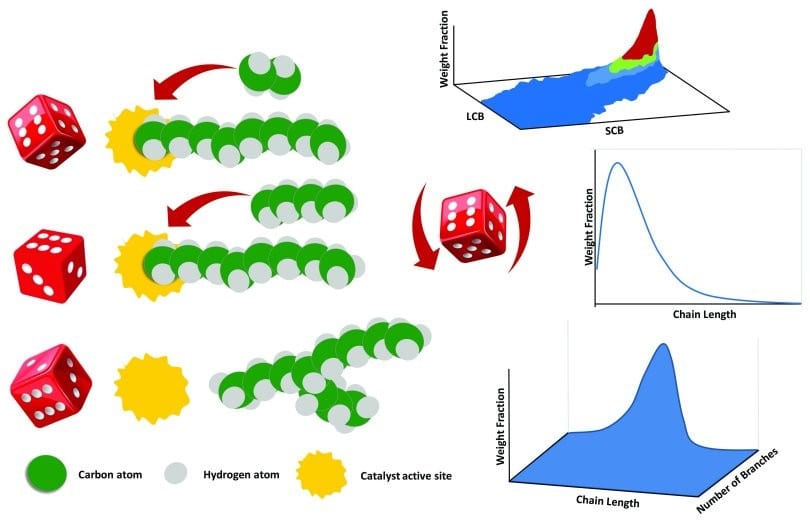

MC methods are particularly useful in polymer reaction engineering studies because they can predict the molecular architecture of polymers with a richness of detail that no other modeling technique can capture.

One of the advantages of MC methods is that differential or algebraic equations are not required to predict the microstructures of polymers made in batch, semi-batch, or continuous reactors. In its simplest implementation forms, no knowledge of advanced mathematics is required to develop MC models; they only require the knowledge of a polymerization mechanism expressed as a series of elementary steps, probabilities associated to each of these steps, and a random number generator. Armed with these basic concepts and a good knowledge of programing techniques, polymer reactor engineers can develop MC programs to describe polymerization systems varying from simple single-phase polymerizations operated at steady-state conditions to rather complex multiphase dynamic systems.

Therefore, MC methods help us understand the many microstructural details of a polymer population much better than any other mathematical modeling technique. Since polymer microstructure ultimately determines how the polymer will behave macroscopically, this understanding has fundamental and practical value. MC simulation is the best tool polymer reaction engineers and scientists have in their toolbox to explore how different polymerization mechanisms and reactor conditions determine polymer microstructure. Other modeling methods can also be very useful, but none predicts so many details as MC methods.

Therefore, MC methods help us understand the many microstructural details of a polymer population much better than any other mathematical modeling technique. Since polymer microstructure ultimately determines how the polymer will behave macroscopically, this understanding has fundamental and practical value. MC simulation is the best tool polymer reaction engineers and scientists have in their toolbox to explore how different polymerization mechanisms and reactor conditions determine polymer microstructure. Other modeling methods can also be very useful, but none predicts so many details as MC methods.

MC methods will become increasingly more important as polymers are needed in more sophisticated applications, and as structure-property relationships are better quantified. The main criticism against MC methods in the past has been their long computation times. The development of faster personal computers, as well as the easier access to parallel computing and computer clusters, is rapidly dismissing this criticism. In addition, the ingenious work of several researchers has led to faster MC algorithms, either by proposing approximate MC methods and efficient data storage strategies, or by developing deterministic/stochastic hybrid models.

In their recently published Review article, J. B. P. Soares (University of Alberta) together with A. L. T. Brandão, J. C. Pinto (Universidade Federal do Rio de Janeiro) and A. L. Alberton (Universidade do Estado do Rio de Janeiro) give a critical overview of the literature on steady state and dynamic MC methods in polymer reaction engineering. Their aim is to convince the readers that playing dice regularly can be a great asset to polymer reactors engineers and scientists.