During the last decade, laser sintering (LS) has become one of the most promising polymer Additive Manufacturing techniques, capable of manufacturing 3‐dimensional (3D) products with complex and accurate geometries from powdered materials. Polyamide 12 (PA12) powder is frequently selected for LS applications due to its ease of sintering, large processing windows, high laser energy absorption, and good mechanical properties. LS‐PA12 parts with many other polymers have also restricted applications where adhesive bonding of polymers with other materials, wettability, or printability are required, due to their poor hydrophilic properties. PA12 powder tends to have the lowest swelling and solubility in polar solvents like water due to its longer methylene chain and strong hydrogen bonds between the amide groups of the PA12. Consequently, different surface modification techniques, for instance, wet chemical and/or plasma treatment have been frequently used to modify the polymeric surfaces for such applications.

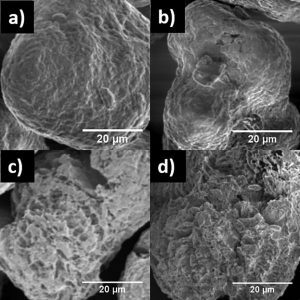

High magnification SEM images of (a) PA12 without LP‐PT plasma treatment (b) 1 h LP‐PT treated PA12, (c) 2 h LP‐PT treated PA12, and (d) 3 h LP‐PT treated PA12

Plasma‐ a reactive medium containing free electrons, excited and ionized atoms and molecules, radicals, and metastables and VIS‐UV radiation is widely applied for chemically modification of polymer surfaces, e.g., ultrafine cleaning, functionalization and etching. Atmospheric pressure plasma jets are used to improve the wettability and adhesion, as is low pressure plasma. Plasma‐based surface modification has been used extensively in the past decade due to its favorable properties, such as lack of toxic chemicals or waste products; therefore, it is considered as an environmentally friendly method.

A team of researchers from Iran, the United Kingdom and Germany studied the effects of plasma treatment on the sintering of PA12 using different plasma techniques: low pressure air plasma treatment (LP‐PT) and two atmospheric pressure plasma jets K‐APPJ and H‐APPJ. “The LP‐PT treated PA12 powder became wettable, denser, and porous which results from the incorporation of oxygen groups, dissociation of carbon bonds with the accompanied removal of volatile products and amorphous components” according to team member Alaa Almansoori. Although further work and testing on characterizing the chemical and physical changes of K‐APPJ and H‐APPJ treated PA12 using techniques such as FTIR and wettability analyses will be required, the team sees the PJ treatment technique for laser sintering applications of PA12 powder as promising.