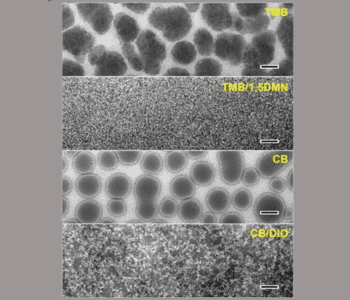

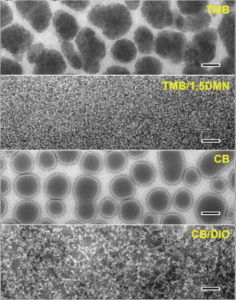

Transmission electron microscopy images show the stark morphological differences of PSCs processed by different solvents. The scale bar is 200 nm.

A team of US and Chinese scientists has demonstrated a new, nonhalogenated solvent system to produce polymer solar cells (PSCs). The environmentally-friendly process produces PSCs with a much better power conversion efficiency (PCE) than conventionally prepared devices.

To date, most high performance PSCs are fabricated using chlorinated solvents, which offer almost ideal conditions to control the active layer morphology of bulk heterojunction solar cells. However, the toxicity of these solvents has driven the development of processes based on nonhalogenated solvents, which could then be scaled for industrial manufacturing.

Using dithienosilole and thienopyrrole-4,6-dione (PDTSTPD) as the donor polymer, the researchers produced optimized PDTSTPD:PC71BM-based PSCs with an inverted structure. Four processing solvents were investigated: 1,2,4-trimethyulbenzene (TMB), TMB with 30 mg mL-1 1,5-dimethylnaphthalene (1,5-DMN) as a processing additive, chlorobenzene (CB), and CB with 1,8-diiodooctane (DIO). CB and DIO make up a commonly used halogenated solvent-additive pair.

The current–voltage characteristics of the PSCs were compared against a CB–DIO-processed reference device. The nonhalogen-processed PSCs met or surpassed the performance of the reference device with a PCE > 8%, an open-circle voltage (VOC) of 0.90 V, a short circuit density (JSC) of 13.42 mA cm-2, and a fill factor (FF) of ≈70%. The influence of the device structure with this solvent effect was tested, with results suggesting that other device architectures may also benefit from this strategy.

The morphology and performance relationship between the host solvents and additives were extensively investigated through a range of methods. Good performance was shown to correlate with a finely distributed nanomorphology, as well as a well-defined polymer fibril network structure. The research represents an important step towards higher performance and less hazardous processing for PSCs. For comprehensive details, readers are referred to the full publication.

Advanced Science is a new journal from the team behind Advanced Materials, Advanced Functional Materials, and Small. The journal is fully Open Access and is free to read now at www.advancedscience.com.