Thinking of NMR brings to mind large machines with superconducting magnets. One finds them in chemical research institutions to unravel molecular structures and in hospitals to measure images through soft tissue. But small machines exist that are portable and suitable for materials testing at the site of the object.

Thinking of NMR brings to mind large machines with superconducting magnets. One finds them in chemical research institutions to unravel molecular structures and in hospitals to measure images through soft tissue. But small machines exist that are portable and suitable for materials testing at the site of the object.

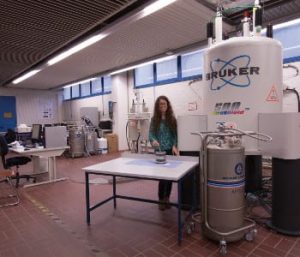

Teymouri, Kwamen and Blümich from RWTH Aachen University have studied the degradation of factory-grade LDPE (low-density polyethylene) pellets when exposed to air at different temperatures with a desktop NMR machine that uses a compact, permanent magnet and is maintenance-free. This user-friendly device delivers NMR relaxation data, which report the concentration and mobility of the crystalline, interfacial and amorphous domains of the semi-crystalline polymer and their changes with progressive aging.

According to the researchers, sample preparation and measurement are simple and fast, and their NMR observations are in agreement with more demanding DSC, FTIR, and SEC measurements. During the aging process, crystallization and chemical degradation progress at different rates. While at temperature below 90° C crystallization dominates, oxidative degradation takes over after 28 days when aging at 100° C. LDPE degrades chemically by crosslinking and chains scission, whereby chain scission dominates at long aging times.

However, in addition to time and temperature, the molecular weight distribution plays a role in the aging process. In nearly all factory-grade polymer materials a considerable fraction of oligomers and low-molecular weight polymers is contained as wax. Their NMR data reveal that the wax content can accelerate the aging process and increase the crystallinity during thermal aging.