Metallic nanostructures have proven to be among the most flexible nanomaterials because of the synthetic control of their size, shape, and composition, as well as the resulting tunable optical properties. Gold nanoparticles (AuNPs) are among the oldest forms of engineered nanostructures with multi-discipline applications such as medical theranostics, surface‐enhanced Raman spectroscopy, and as seeding sites for other materials.

Most synthesis methods of AuNP production involve wet chemistry‐based approaches. In solution‐based routes, the AuNPs typically end up solubilized in water or other solvents using surfactants, which is useful for some applications, but this can also increase contamination for many post-processing purposes. To eliminate the possibility of contamination in post-synthesis reactions and applications, there is interest in routes for synthesizing AuNPs in the gas phase. Pre-existing gas phase methodologies include inert gas condensation, spark ignition, plasma sputtering, and hot‐wire synthesis.

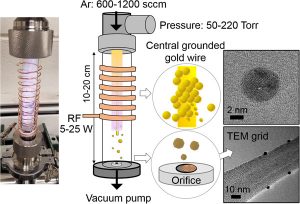

Photograph and schematic of plasma‐based gold nanoparticles (AuNPs) synthesis. Insets show transmission electron microscopy (TEM) images of AuNPs.

Recently, scientists have turned to flow‐through plasma synthesis of metallic nanoparticles and nanostructured films. The advantages to these plasma‐based methods are a relatively narrow size distribution and continuous synthesis.

Now, researchers from the Department of Mechanical Engingeering at Michigan State University have developed a new method for making AuNPs based on a radiofrequency (RF) plasma together with a consumable Au electrode for the synthesis of monodisperse AuNPs.

Their new gas‐phase method, which is based on an RF plasma, produces AuNPs in a more sustainable way. For comparison, the team also produced AuNPs by hot‐wire method at low pressure. This new plasma‐based approach results in a smaller average size and smaller overall distribution of sizes per sample, as compared to the hot‐wire method.

While these are important first steps, there is still work to be done. “Future work will explore methods to increase the production yield as well as control the AuNP diameter using the plasma method, along with efforts to employ this facile technique to the synthesis of other metallic NPs”, says Rebecca J. Anthony, corresponding author of the study.