Grain size represents a critical parameter in all polycrystalline metal solids because it plays a major and often dominant role in determining both the strength and ductility of the metals. In broad terms, the strength at room temperature is increased and the forming properties at elevated temperatures are enhanced when the grain size is reduced. Accordingly, much attention is devoted in industrial practice to the use of thermo-mechanical treatments, which are designed to introduce limited grain refinement to reduce the grain size of metals to values below ~2-5 µm. Because of this limitation, considerable attention has been directed towards devising alternative procedures, such as processing using severe plastic deformation (SPD) techniques, which produce very high strains without the introduction of any significant changes in the overall dimensions of the work-pieces. In practice, SPD processing provides the potential for exceptional grain refinement leading to ultrafine-grained (UFG) metals with grain sizes within the nanometer range.

In a recent report in Advanced Engineering Materials, Megumi Kawasaki and Jae-il Jang of Hanyang University, South Korea, Byungmin Ahn of Ajou University, South Korea, Praveen Kumar of Indian Institute of Science, India, and Terence G. Langdon of the University of Southampton, U.K., have focused on the recent substantial breakthroughs that have been achieved in UFG metals using processing by SPD to address the paradox of strength and ductility. This paradox states that metals having small grain sizes generally exhibit high strength but very limited ductility at room temperature, however recent experiments demonstrate that it is possible to achieve good ductility by imposing a sufficiently high strain in the SPD processing.

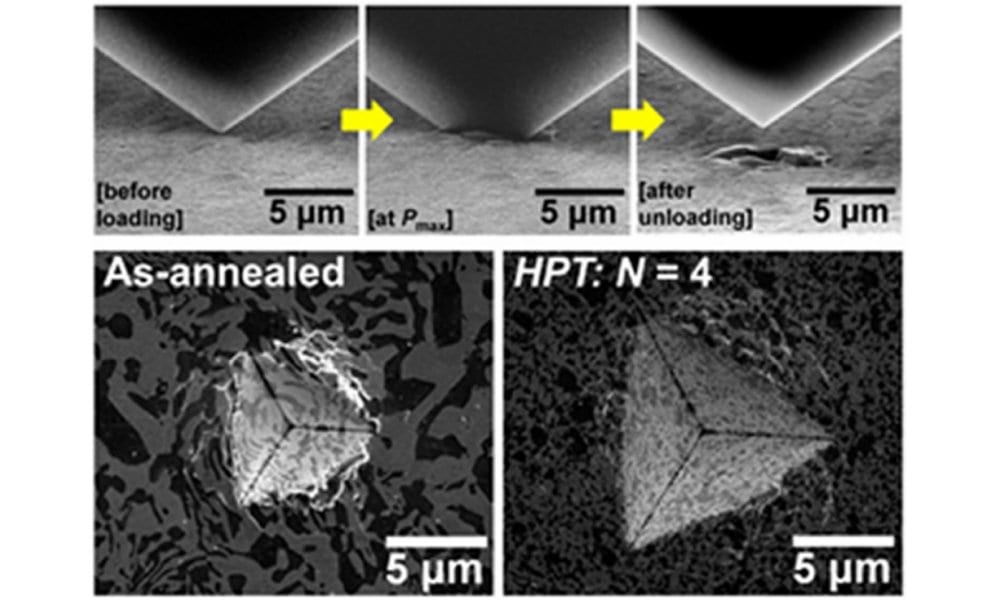

With the advances in SPD techniques, it is necessary to apply appropriate characterization techniques to measure the mechanical properties of the UFG metals. Thus, the novel technique of nanoindentation was applied to evaluate the mechanical behavior in local areas of the UFG materials in order to provide detailed information on the properties and the strain rate sensitivity. The authors show that, in addition to conventional tensile testing, the nanoindentation technique is exceptionally promising for UFG materials where the samples may have small overall dimensions and include gradations in the microstructure. This report documents the successful application of this approach in examining the micro-mechanical responses of a variety of engineering materials including a magnesium alloy, a two-phase alloy, a high entropy alloy and a nanocomposite processed by high-pressure torsion.

Accordingly, the review summarizes the available experimental results showing enhancements in strength and ductility in terms of the micro-mechanical response analysed through the nanoindentation technique at room temperature in a range of UFG metals after several different SPD processing procedures.