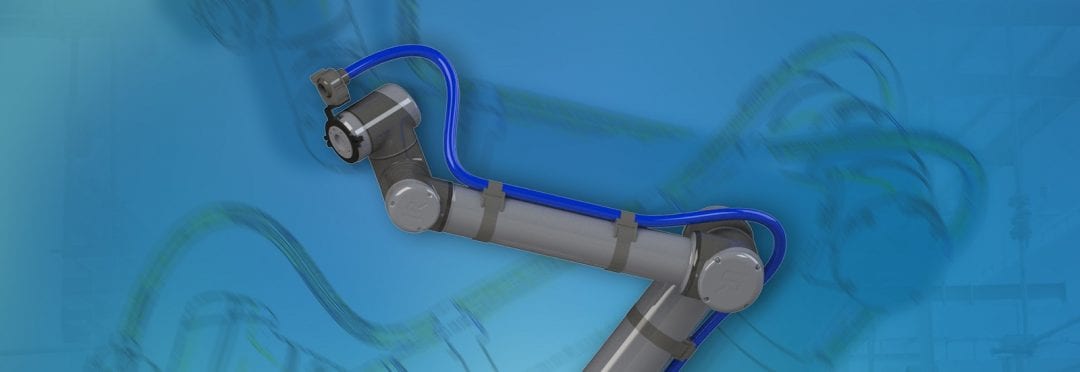

Robots are virtually indispensable from nearly all fields of production. Thus, supplier of cables and cable systems Leoni intoduced a thermoplastic material that offers versatile use on robot arms. The company calls the flexible, slip-resistant attachment solution for lightweight robots B-Flex.

The basic principle behind the solution is simple: consisting of two components, the hook-and-loop straps and the flexible mounts, the hook-and-loop strap is threaded into the matching insertion slots on the mount for installation on the robot. The mounts are then positioned in the chosen location on the robot and the components are then inserted between the hook-and-loop strap and mount. As a last step, only the hook-and-loop strap needs to be pulled tight and closed.

This quick and simple tool-less installation could be a real advantages as it is also suitable for making quick repairs by fastening components to larger robot arms or the conduit, according to Leoni. Thanks to the thermoplastic material, which gives the mounts their flexibility, the new solution can also be used on a wide variety of surfaces, sections and circumferences without the risk of slippage.

Furthermore, the system is suitable for use with collaborative robots that work side-by-side with human operatives: the pliant material prevents injuries due to sharp edges. As the company reports, the mounting solution weighs very little and has very few protrusions thanks to its low-profile design.

The Germany based company expects to have a solution for application scenarios and markets in which lightweight and collaborative robots are now being deployed. These range from activities such as deburring, populating, packing and assembly in existing industries through to deployment in entirely new markets such as watchmaking, pharmaceuticals, chemicals and furnishings.