The solidification of metals is critical to the manufacture of components used in our everyday lives, from cast aluminum alloy engine blocks to single crystal superalloy turbine blades. Although we commonly see materials like water crystallize or ice melt, visualizing crystals solidifying in metals is more challenging, but no less important.

The solidification of metals is critical to the manufacture of components used in our everyday lives, from cast aluminum alloy engine blocks to single crystal superalloy turbine blades. Although we commonly see materials like water crystallize or ice melt, visualizing crystals solidifying in metals is more challenging, but no less important.

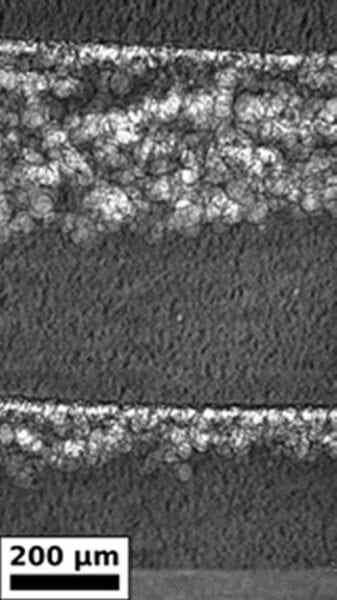

Researchers from Los Alamos National Laboratory, Argonne National Laboratory and Brookhaven National Laboratory use x-ray imaging and controlled solidification to watch and understand how crystals evolve in metals.

These observations are used to highlight gravity-related, singular crystallization events that may constitute the origin of casting defects for some processing scenarios. Moreover, it is illustrated how real time feedback can be used to manipulate microstructural evolution and produce unconventional microstructures.

This work will lead to the creation of metals with designed structures, properties, and performance and enable the rapid deployment of advanced manufacturing technologies.