Disks of an extruded magnesium WE43 alloy are processed by high-pressure torsion (HPT) under a pressure of 6.0 GPa for 5 and 10 turns at room temperature and the evolutions of microstructure and mechanical properties are investigated in detail. Excellent grain refinement is achieved by the HPT processing with a reduction in grain size from an initial value of ~12 µm to a final value of ~200-300 nm after 10 turns.

The microhardness increases significantly with the HPT processing, but low hardness values are recorded at the centers of the disks even after 10 turns. The evolution of hardness values is attributed to the shear strain accumulation at different positions within each disk during the deformation process. There is a very slow hardness evolution towards a more homogenous condition and the hardness variation across the disk is large even after 10 revolutions of HPT.

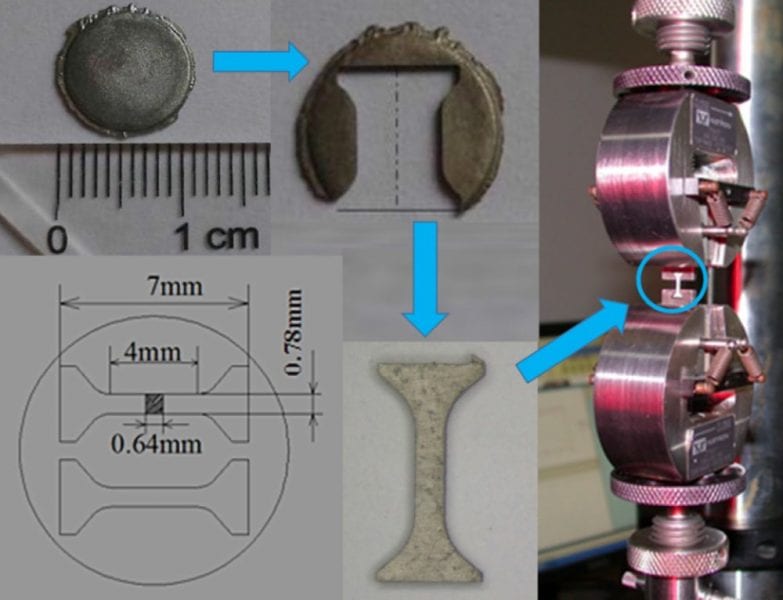

The results of tensile testing at room temperature demonstrate that the tensile strength initially increases and then decreases while the elongation decreases. The ultimate tensile strength increased from ~244 to ~256 MPa after 5 turns due to fine-grain strengthening and dislocation strengthening, but it is reduced to ~202 MPa after 10 turns because of the inhibitory effect of grain boundary on the decreased dislocation movement. Observations of the fracture surfaces reveal a corresponding transition of the fracture mode from ductile to brittle.

Significant grain size refinement can be achieved by subjecting materials to deformation of HPT and this approach can produce an ultra-fine crystal structure. It is necessary to introduce new metal forming technology to improve the mechanical properties of biomedical magnesium alloy materials. For biodegradable magnesium alloy, it is important to improve the strength, hardness and toughness and also to simultaneously improve the forming capability.