Researchers at Florida International University have developed novel micro-supercapacitors with exceptional high power performance and frequency response. Supercapacitors are electrical storage devices with higher energy density compared to conventional capacitors and higher power density compared to batteries. The developed micro-supercapacitors use reduced graphene oxide as the capacitive material. Each device has two sets of micro-sized interdigital electrodes that are assembled on a single chip. These microdevices are expected to power small electronic devices such as embedded sensors, biomedical implants, and RFID tags, among others.

As explained by Dr. Chunlei Wang, associate professor of material science and engineering and the research team leader; “The developed micro-supercapacitors have a unique combination of high volumetric capacitance and high power density and can be charged and discharged at extremely high rates which makes them suitable for applications that need high energy in a very short period of time.”

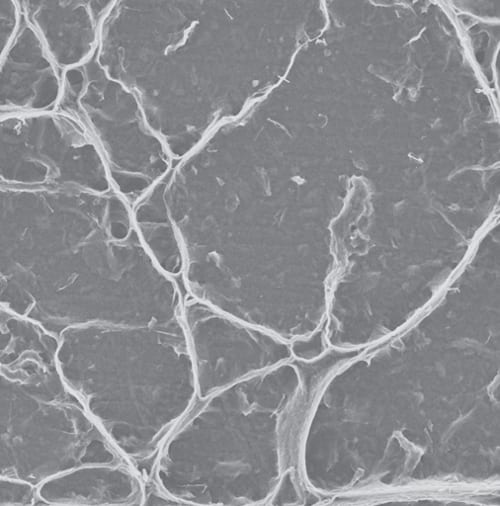

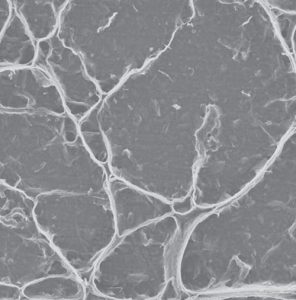

Graphene sheets with a high specific surface area, non-porous structure and high conductivity are ideal electrode materials for high power supercapacitors. The best synthesis method for large quantities of graphene is thorough reduction of single layer graphene oxide. According to Majid Beidaghi, a doctoral candidate and the first author of the article: “The main challenge in using graphene as an electrode material is that the single sheets tend to agglomerate and restack during reduction of graphene oxide or during electrode fabrication. This limits the accessibility of electrolyte ions to the graphene sheets and therefore hinders the electrochemical properties of the electrodes.”

In their article, Beidaghi and Wang explain how a rational design of the device architecture by having side-by-side micro-sized electrodes and using CNT as nano spacers between the graphene sheets increases the accessibility of the electrolyte ions to graphene sheets and results in high power density and exceptional rate handling ability and frequency response. A simple and scalable two-step fabrication method was used to fabricate devices.