Hydrogels, or water swollen polymer networks (think jelly), are commonplace in many fields of research due to their similarity to native tissue. Combining these soft materials with other more sturdy ones is a good way to fabricate hybrid structures with tailorable properties.

Combining different materials, particularly those with diverse or tailorable biological and mechanical properties, is advantageous for a number of applications. Studies have shown that metal/hydrogel hybrids can be used for synergistic materials in hydrogel painting, sensors, and soft robots. However—as one might imagine of trying to ‘glue’ jelly to a spoon—this is no easy feat. The tough bonding, and in particular, on-demand debonding, between these distinctly different materials has remained a challenge.

In a recent publication in Advanced Materials, researchers have investigated the reversible bonding of hydrogels and metals. This combination brings the strong mechanical properties of metal like stiffness, fatigue resistance, and strength, together with the biological compatiblity and activity of hydrogels.

“Potential applications may include for example, when medical metal implants are combined with bioactive hydrogels for modulating their surface properties to promote tissue integration,” suggests Professor Y. Shrike Zhang from Harvard Medical School.

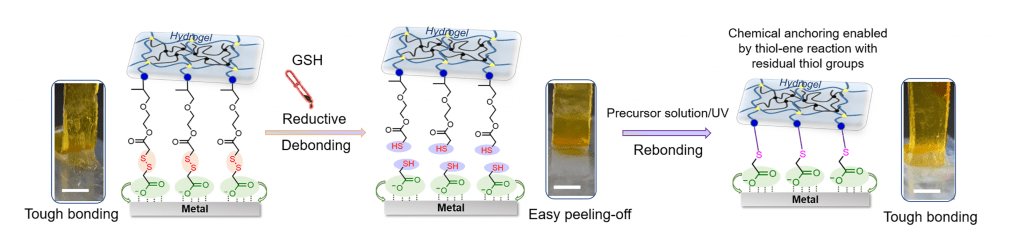

By functionalizing various metals with a small molecule linker, a reactive surface is created, which can bind to complimentary species in the hydrogel to form interfacial covalent bonds. After adding a reducing agent, the ‘debonding’ stimulus, the hydrogel can simply be peeled off of the metal. A secondary reaction shows that the adhesion is successful over multiple cycles without the need for further functionalization of the metal surface.

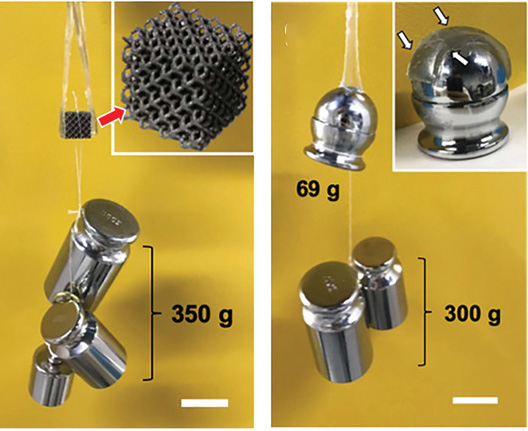

The researchers show that this method can be applied to both curved, flat, and even complex 3D surfaces, and preliminary studies indicate good compatibility with cells for potential biomedical applications.

“These results provide a higher level of flexibility and functionality towards rational design of ‘smart’ materials and devices interfacing hydrogels and metals for wide applications in dynamic and complex situations,” states Prof. Kan Yue of South China University of Technology.