Donor tissues and organs are in limited supply. Waitlists, host immune responses, and biomechanical mismatches complicate the matter even more. But what if there was an alternative?

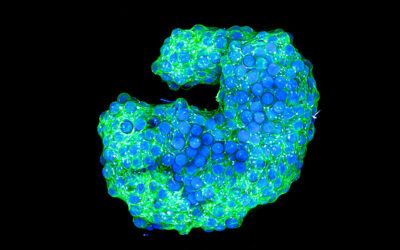

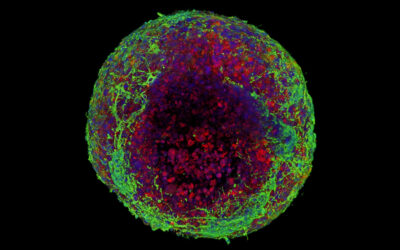

We are at a point in science where we can engineer and manufacture human tissues and organs in labs, said Dr. Rohan A. Shirwaiker, an associate professor in the Edward P. Fitts Department of Industrial and Systems Engineering at NC State. However, it is not as simple as mixing cells with other raw materials in a test tube. “Natural tissue structures harmonize across the macro, micro, and nanodomains, resulting in multiscale constructs whose functional properties support the biomechanical and physiological roles they play in the human body,” said Shirwaiker.

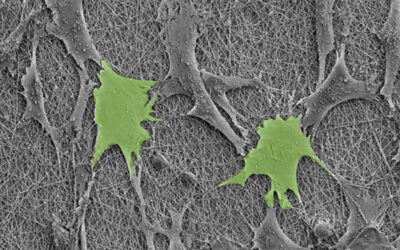

“In engineering biomimetic tissues and organ substitutes, it is essential to use manufacturing processes that can accurately rebuild the natural organization of cells and extracellular matrix in the tissue, which is important for the artificial tissue’s function,” added Dr. Parth Chansoria, currently a postdoctoral research associate in the Eshelman School of Pharmacy at UNC-Chapel Hill.

In deciding how to manufacture a tissue replacement, an extensive array of biofabrication processes, each with technical advantages and limitations relating to the ease of use, biocompatibility, operational cost, and versatility have to be carefully considered. Karl Schuchard, a Ph.D. student in Dr. Shirwaiker’s lab added, “rarely can an individual process create tissues which comprehensively imitate the form and function of human organs and tissues.”

Enter hybrid biofabrication processes, which synergize two or more independent processes to complement the strengths and limitations of one another. In their recent review article published in WIREs Nanomedicine & Nanobiotechnology, Shirwaiker, Chansoria, and Schuchard explore hybrid biofabrication process designs for engineering biomimetic tissues, as well as recent advances comprising the hybridization of processes based on fiber and fabric formation, additive manufacturing, surface modification, remote-fields, and other notable principles.

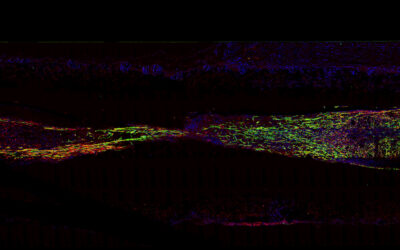

As an example of such hybridization, remote field-based processes employing acoustic fields, such as ultrasound, are advantageous for patterning and stimulating cells, while a process like extrusion 3D bioprinting is capable of creating structures that match the patient due to its excellent material placement capabilities. These processes harmonize when synergistically integrated as the new process, ultrasound-assisted bioprinting, can serve as an effective strategy to create complex tissues, such as the knee meniscus, where their macro-geometry and unique internal organization of cells and extracellular components is critical to their function.

But, there is more work to be done! “In order to facilitate faster clinical translation, in addition to developing and enhancing application-specific hybridization schemes, appropriate automation strategies that enable reliable, reproducible, and efficient manufacturing of biomimetic tissue constructs should be explored,” said Shirwaiker. ”Using indexing mechanisms similar to the ones used in CNC machines or gantry systems similar to many 3D printers, deploying multiple biofabrication processes simultaneously or sequentially could be a solution.”

Further, the synchronization of operations could be controlled via custom or open-source software. According to Chansoria: “Where integration of processes into indexing or gantry mechanisms is not feasible, one or more robots could be deployed to selectively pick up required tool heads and for material handling and transfer operations between dedicated processing stations.”

Research on databases, bioinformatics, machine learning, and artificial intelligence pertaining to hybridization will open opportunities for optimizing application-specific design and manufacturing schemes. “Successful development and adaptation of these allied technologies into tissue engineering can lead to smart systems to help identify optimal hybrid material formulations and hybrid processing strategies to create biomimetic tissue constructs,” said Schuchard.

Ultimately, such collective advances will lead us to superior “living” tissue and organ substitutes that can be used to treat patients in lieu of donor grafts and metal and plastic devices.

The review by Chansoria, Schuchard, and Shirwaiker outlines a roadmap towards engineering biomimetic tissues by providing critical insight into recent advances and future outlook of hybrid biofabrication.

Reference: Chansoria P, Schuchard K, Shirwaiker RA. Process hybridization schemes for multiscale engineered tissue biofabrication. WIRES Nanomedicine & Nanobiotechnology (2020). DOI: 10.1002/wnan.1673