Dr. John Uhlrich, Editor-in-Chief of Energy Technology, talks to Professor Christos Maravelias of the University of Wisconsin–Madison, USA, and Dr. Jeffrey Herron, now of The Dow Chemical Company, about their recent article on a systems level approach to biomass upgrading strategies for the next-generation biorefinery. The work identifies important future areas for process improvement by detailing the key trade-offs between various process design options for producing biofuels and chemicals from biomass, and is included in a Special Issue on Pyrolysis for Energy Technologies.

Primary Investigator Prof. Christos Maravelias (left) and lead author Dr. Jeffrey Herron (right).

- Could you briefly explain the focus and findings of your article to a non-specialist and why they are of current interest?

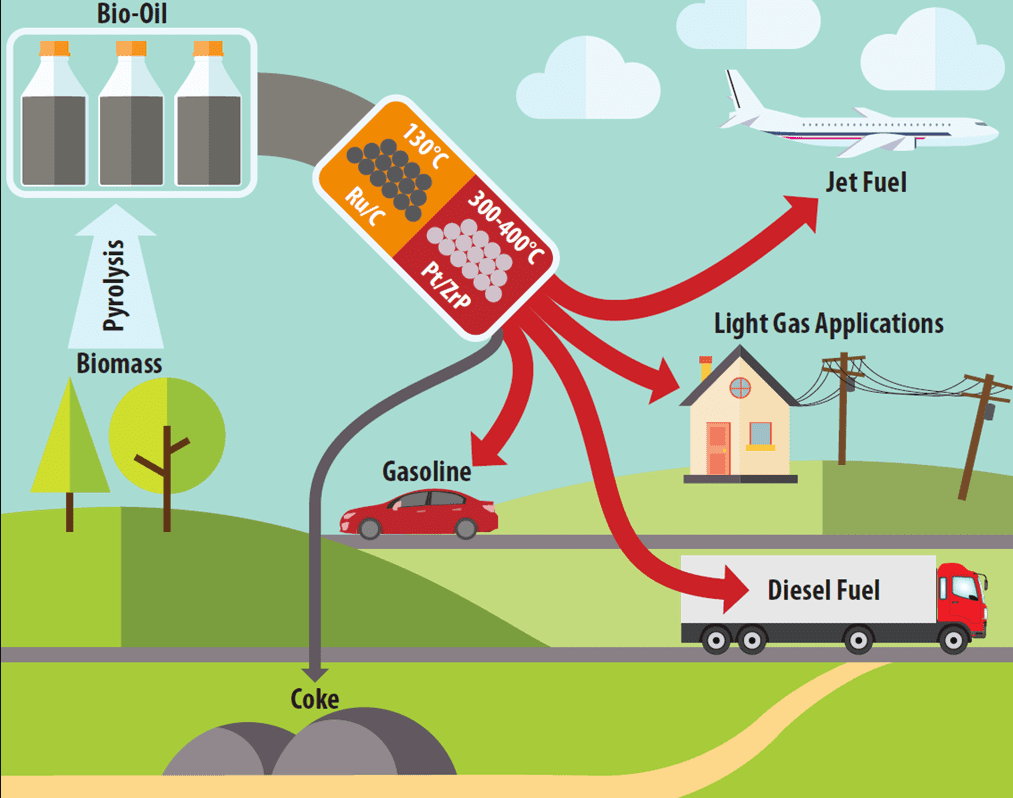

One of the principal routes for converting biomass to fuels is thermal decomposition (i.e., pyrolysis at 500-850 °C) followed by catalytic upgrading. One of the key challenges in this approach is that there is a wide product distribution of unstable, corrosive products. A possible improvement on this process is to thermally fractionate the biomass over several thermal decomposition stages, which can provide several product streams, each with a narrower product distribution. The article describes a high-level, process systems engineering-based assessment of the key trade-offs and considerations for designing a biofuels refinery that employs thermal fractionation technology. The main take-home message of our work is that the optimal plant design requires simultaneous optimization of the thermal fractionation process with the choice of catalytic upgrading.

- Could you please explain the motivation behind the study?

Though there has been considerable effort towards understanding the product distribution of biomass thermal decomposition, as well as identifying possible chemistries to upgrade the product, guidelines for determining how to integrate the thermal decomposition with the chemistries has been lacking. Furthermore, as there are a wide-variety of chemistries that can be employed for catalytic upgrading, determining which are the most viable and efficient for utilizing the biomass is important to help focus future research in this area.

- How long did this investigation take?

This instigation has been a collaborative effort among various groups, and took approximately one year to complete.

- What is the general role of such a systems-based approach to the development of the next-generation biorefinery? And to other emerging energy technologies?

Process systems engineering provides important guidance on the feasibility of processes and can be effective in identifying gaps in technology and determining critical technological milestones that must be reached. For biorefineries and other emerging renewable energy technologies, systems-based approaches help us determine which of those can be economically-viable, and what advances must be made to become economically-viable.

- Towards realizing a biomass-to-fuels process, what are some of the most important areas for future development that were identified in your study? Did anything surprise you about your findings?

As we noted before, the design of an efficient process requires simultaneous optimization of the thermal decomposition process and the catalytic upgrading process. Another critical aspect to consider are the separations that may be necessary to design an integrated process based on the ideas presented in the paper. In our work, we describe scenarios where separations allow one to design a more attractive process. Future work in this area must continue to take a holistic approach the problem.

The most surprising finding was that decomposing each component of biomass (i.e., cellulose, hemicellulose, and lignin) in its own fraction may not be the best option. That configuration seemed logical, but efficient upgrading required components from multiple stages.

- How will you follow up on this work?

Now that we have performed a high-level assessment of various process configurations, the next step is to perform a detailed technoeconomic analysis on the most-promising processes that we have identified.