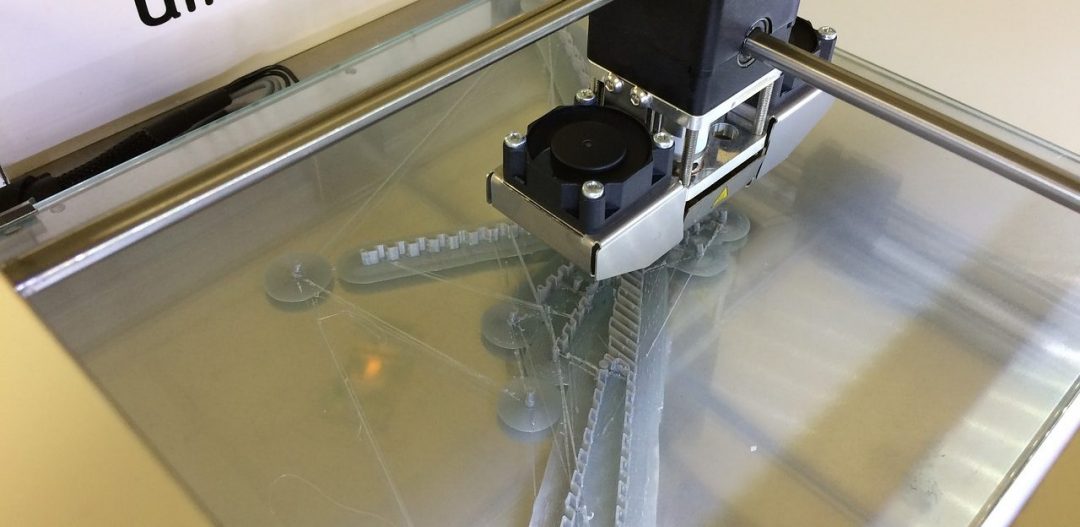

Additive manufacturing (AM) also known as three-dimensional (3D) printing, is a process where parts are generated layer by layer. It has increasingly been used for advanced applications including the printing of adaptive structures utilizing a shape memory polymer.

One approach to AM is called fused deposition modeling (FDM). In this approach the polymer is extruded through a nozzle that traces the part’s cross sectional geometry layer by layer. The nozzle contains resistive heaters that keep the polymer at a temperature just above its melting point so that it flows easily through the nozzle and forms the layer. The most commonly used polymers for AM are acrylonitrile butadiene styrene (ABS) and polylactic acid (PLA).

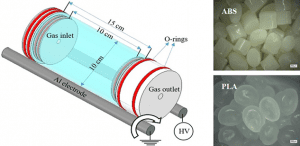

Plasma treatments have previously been applied to modify surface properties of polymer particles by cleaning the surface, by altering crystallinity or by cross-linking and the introduction of polar groups on the surface, without changing the bulk composition. A new study by researchers from the School of Mechanical and Materials Engineering in Dublin, Ireland, reports the performance of barrel atmospheric plasma system for the pre-treatment of both ABS and PLA polymer particles prior to filament formation.

Schematic diagram of the plasma barrel reactor (left) and images of the polymer particles used in the study.

The effectiveness of the barrel plasmas for the pre-treatment of powders has been known, but this team studied the effect of systematically altering the atmospheric plasma treatment conditions on the level of polymer particle activation.

The tensile strength of AM printed samples fabricated from ABS and PLA, were found to increase after plasma pre-treatment of the polymer particles. The plasma pre-treated samples also exhibited increased structural cohesivity during testing, with the three-dimensional structure remaining intact until the moment of failure.

The use of the plasma pre-treatment of both the polymer particles and filaments yielded an increase in the maximum tensile strength of 22 and 16% for AM fabricated ABS and PLA dog bone samples respectively.

“Based on ultrasonic solvent cleaning study carried on PLA particles, we can conclude that plasma activation as opposed to contaminant removal, is the most significant contributory factor to achieving the enhanced mechanical strength of the AM tensile test samples” according to team member Denis Dowling.