Hydrogen has been touted as a potential solution to the world’s energy crisis. However, sustainable and scalable production of hydrogen remains a challenge in the development of proton exchange membrane (PEM) fuel cells and vehicles powered by hydrogen fuel cells.

Producing hydrogen by water electrolysis is one strategy; however, to overcome the high overpotentials of water electrolysis, efficient hydrogen evolution catalysts, especially those based on non-noble metals, are key to a successful hydrogen economy. Current non-noble metal catalysts for the hydrogen evolution reaction (HER) mainly exhibit high activity in acidic media. However, for the oxygen evolution reaction (OER), the counterpart of HER, most of the reported catalysts are efficient only in alkaline conditions.

“So, for practical applications, HER catalysts working just in acidic conditions are technologically and commercially limited due to the lack of efficient and affordable counter electrodes,” says Shuang Li from Technische Universität Berlin, who reports a novel strategy for synthesizing hierarchically mesoporous molybdenum (Mo)-based carbon electrocatalysts.

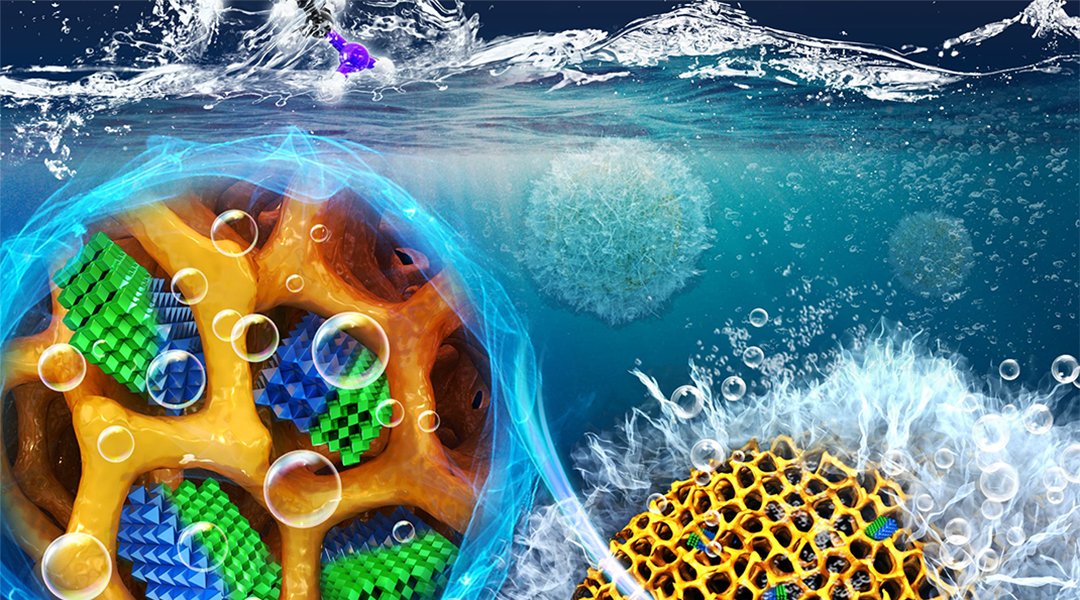

Unlike previous strategies, the approach described in this study is feasible for large-scale production on account of its speed and eco-friendly reaction medium. By using a water-processable dopamine-molybdate precursor, small Mo-based nanocrystallites are generated within the porous carbon material.

“Indeed, we have found nanocrystallites of Mo2C and Mo2N in close proximity and these heterojunctions are the most active center in our mesoporous Mo-based electrocatalysts,” says Shuang Li. The mesoporous catalyst shows excellent hydrogen evolution activity under alkaline conditions, outperforming platinum/carbon—the current state of the art for HER.

The next step for this research is to fabricate a lab-scale water electrolysis device for further testing and optimization in alkaline conditions, as well as seawater. This strategy could be extended to the production of other advanced mesoporous carbon materials and electrodes for a broad range of applications.