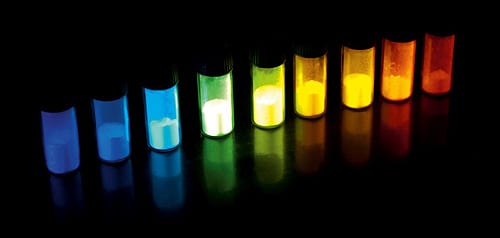

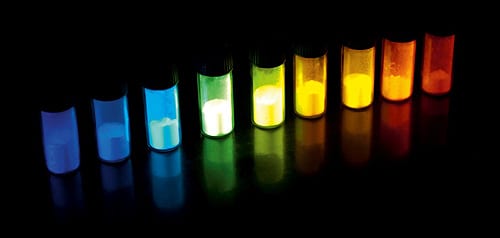

The company cynora focuses on researching organic semiconductors. Now, cynora proposes an innovative concept for solution-based manufacturing of OLEDs for displays, lighting and flexible packaging. The company states that this paves the way for creating displays, light panels and flexible luminescent foil that for the most part can be manufactured using printing and coating processes. The ability to synthesize new luminescent materials will in future enable to address the entire color spectrum. The modular emitters are copper-based molecules, i.e. metal complexes. These metal complexes consist of a metal core surrounded by a ligand shell that plays a major role in determining the properties of the complex. By modifying the ligands it is possible to precisely modulate key properties such as color and solubility.

“Subtle modification of the structure and their corresponding electronic properties of the ligands enable us to fine-tune the color of the light being generated. And we can do that practically across the entire visible spectrum, from red to green to blue,” cynora CEO Thomas Baumann explains the research findings. According to the company, the solubility of the building blocks can be adjusted through further modifications as well – an aspect that is of central importance for the fabrication of OLEDs with solution-based processes. “Because manufacturing organic light-emitting diodes involves processing multiple layers on top of each other, it is especially critical that underlying layers are preserved when the new layer is applied,” says Baumann. “That is why it is important to be able to precisely influence the luminescent material’s solubility and adjust it to the fabrication process. That, in a nutshell, is what we managed to achieve.“

The approach also offers the possibility of turning the applied layers insoluble, effectively preventing undesired blending of the functional layers. This cross linking is achieved through autocatalytic networking of the copper complexes with a host matrix in the drying stage during processing as cynora reports. Baumann on the advantages of this approach: “The functional layer we obtain with this step is ideally suited for the solution-based processing of multilayer systems. It shows greater thermal stability than the non-modified metal complex, and becomes insoluble in all common organic solvents.”