Hybrid materials are composites of several equal as well as different kinds of materials. By using hybrid components the mechanical properties are specifically adapted to the requirements. Thus, time intensive post-treatment processes can be avoided. Ready-to-install and highly functional components can be produced in a few production steps.

Hybrid materials are composites of several equal as well as different kinds of materials. By using hybrid components the mechanical properties are specifically adapted to the requirements. Thus, time intensive post-treatment processes can be avoided. Ready-to-install and highly functional components can be produced in a few production steps.

Challenges of joining steel with aluminum alloys result from the different properties of the two basic elements iron and aluminum. The thermal expansion coefficients and thermal conductivity are significantly different. This may form shrinking gaps in the steel-aluminum parts. To avoid these unwanted gaps it is necessary to achieve a firmly bonded joint between the two materials.

At the University of Hanover in Germany, Bernd-Arno Behrens and Klaus-Georg Kosch searched for the optimum production parameters for compound forging of steel-aluminum parts. Their hybrid specimens consisted of an aluminum core as raw material which was enclosed by a steel casing.

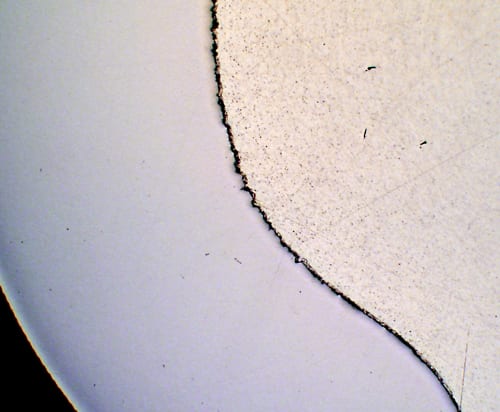

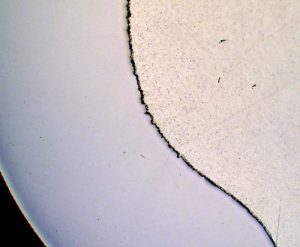

Behrens and Kosch examined untreated, cleaned, and metal-blasted samples. The analysis of the different sample preparations show that cleaning improves the joining zone characteristics. But the joint formation is not affected, the stable aluminum oxide layer remains.

In the following, they investigated the influence of process parameters. Only with a forming temperature above the aluminum melting temperature a phase seam occurred between the components. At a maximum strain rate the researchers noted a positive influence on the joining zone properties. However, by combining and varying different process parameters it was not possible to produce a constant joint between the components.

In the final experiments, Behrens and Kosch investigated the effect of an increasing true strain. The aim was to crack the aluminum oxide layer during forming. The result shows that the factor true strain, and thus the breaking of the aluminum oxide layer, has a strong influence on the formation of intermetallic phases. An increased true strain promoted the formation of a stable joining zone. Moreover, the results show that the thermal expansion of different materials can be compensated by the formation of a stable firm joint.