Tracking and recording our physical movements and sleep patterns is quickly becoming a normal part of our daily routine, leading to increasing efforts to design more efficient wearable electronic devices. Power sources are essential components of these devices, and solar cells have the potential to replace batteries.

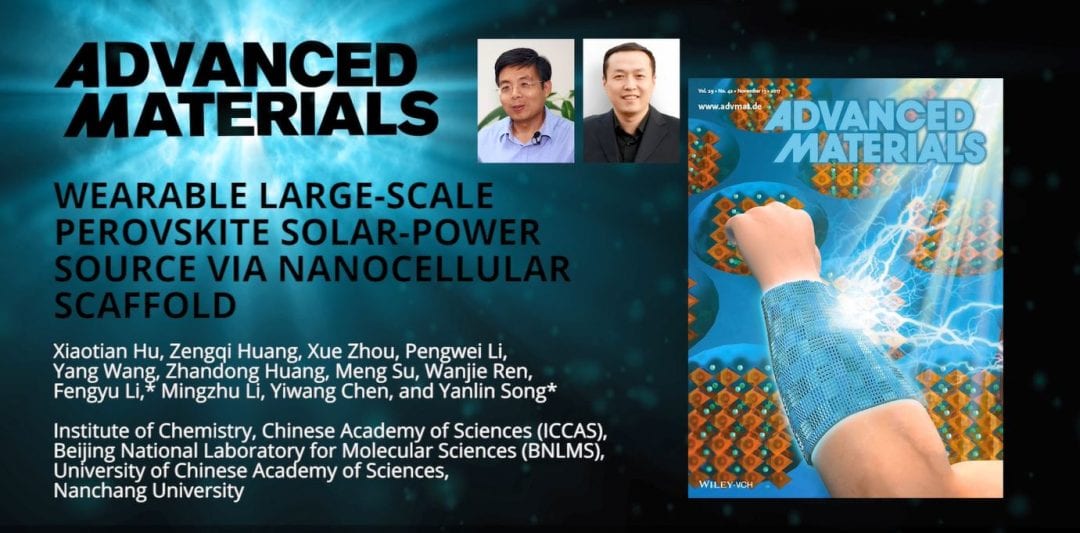

In a communication in Advanced Materials, Fengyu Li and Yanlin Song from the Chinese Academy of Sciences, along with their co-workers, design high-performance flexible perovskite solar cells (PSCs) using green printing technology.

The nanocellular scaffold is fabricated by first spin-coating a monolayer of polystyrene (PS) microspheres onto a transparent electrode. The voids are filled with a mixture of a conducting polymer and poly(styrene sulfonate) (PEDOT:PSS), and the PS microspheres are washed away with toluene to yield a highly crystalline, uniform film, which is integrated into a PSC using the green printing process.

Compared to mesoporous devices, the nanocellular structure enhances transmittance by ≈5% in the visible wavelength range, from 470 to 1000 nm. The reflectance is also reduced by 38% compared to mesoporous devices, signaling improved light-confinement ability. The density of the optical electric field distribution is improved by 27% at the nanocellular PEDOT:PSS layer, and the light intensity is significantly reduced, which are two other indicators of its superior light-harvesting capability.

Current–voltage curves for large-scale, 1 cm2 PSC chips of indicate a significantly higher average power conversion efficiency (PCE) of 12.32%, relative to 7.16% for the device based on the mesoporous hole-transport layer (HTL).

After 1000 consecutive bending cycles on the nanocellular scaffold at a curvature radius of 2 mm, the PCE of the mesoporous device reduces to 49% of its original value before bending, while the nanoporous device retains 93% of its initial PCE. By simulating both upwards and downwards bending deformations, it is clear that the nanoporous PSCs can effectively release stress and are much less prone to fracture than the mesoporous scaffold.

Solar cell modules composed of 24 individual chips could effectively power a fan, and when worn on the arm or torso, could power a wearable electronic device under different body movements, demonstrating its excellent flexibility.

To find out more about this flexible solar cell for wearable electronics, please visit the Advanced Materials homepage.