Rechargeable nickel–metal hydride (NiMH) batteries are used in everyday consumer electronics including cameras and power tools. As these products become more portable, flexible, and wearable, so must the energy-storage device.

In their paper in Advanced Energy Materials, Professor Jie Yu from Harbin Institute of Technology, Professor Chunyi Zhi from City University of Hong Kong, and co-workers develop a modified silkscreen printing and electrodeposition technique to fabricate a thin, freestanding nickel matrix for use as a flexible electrode in high-performance NiMH batteries.

To fabricate porous nickel films (PNFs), insulating ink is first preprinted through a mesh onto graphite paper to control the amount of penetrated ink. The graphite paper is then removed and replaced with a sheet of stainless steel. An insulating ink microarray is printed onto the stainless steel, followed by electrodeposition of nickel onto the insulating template. The nickel sheet is peeled off the substrate, forming a thin, freestanding, flexible PNF. By changing the mesh structure and the position of the platform, the pore size, density, and pattern structure of the PNFs can be easily controlled.

PNF with a pore size of 47 µm and a density of 25 682 pores cm−2 was integrated into a solid-state NiMH full cell. At a power density of 19.2 W kg–1, the maximum gravimetric energy density was 151.8 Wh kg–1, and at a power density of 64.4 W L–1, the maximum volumetric energy density reached 508.5 Wh L–1. These results are superior to other reported flexible energy-storage devices and several important commercially available batteries.

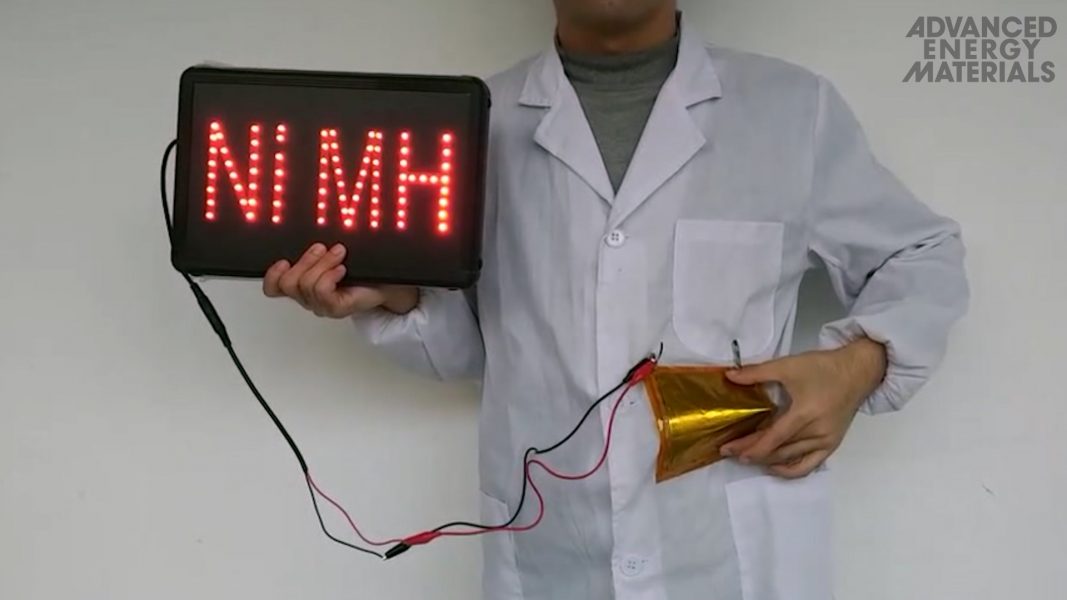

The excellent flexibility of the working cell was demonstrated by bending from 0° to 180°, then charging and discharging at 0.2C. When a cell was bent to 90° 100 times, the discharge capacity stabilized at ≈160 mA h g–1 at 5C, which is comparable to the flat state. Demonstrating its large-scale fabrication, an electric shaver was powered for ≈25 minutes using a 10 × 10 cm2 cell. Connecting two of these cells in series could power a light-emitting diode logo for ≈1.5 hours in both flat and bent states.

To find out more about this flexible NiMH battery, please visit the Advanced Energy Materials homepage.