Advanced Engineering Materials has been bringing you the latest breakthroughs in structural materials that are making those important first steps towards commercialization since 1999. With its further increased, record-high Impact Factor of 2.319 (2017 Journal Citation Reports), the journal covers a variety of key topics, such as composites, ceramics, intermetallics, and coatings, and also high-temperature, cellular, and biomedical materials, with a strong focus on new manufacturing techniques.

No access to our published content? Make sure to recommend Advanced Engineering Materials to your librarian. More information can be found here.

In this monthly feature, we highlight the research behind the artwork on the covers of the most recent issue of Advanced Engineering Materials, as well some of the most read Advanced Engineering Materials publications over the last month. These top-downloaded articles are therefore currently freely accessible! Click on the titles below to get to the corresponding papers. You can find this month’s issue here. Also check out our previous Engineering Digest here and here.

Special Section: Texture and Microstructure of Engineering Materials

Special Section: Texture and Microstructure of Engineering Materials

This special section on “Texture and Microstructure”, guest-edited by Francisco Cruz Gandarilla, Raùl Bolmaro, Claude Esling and Stuart Wright, compiles a selection of reviews and original articles devoted to topics such as recrystallization, deformation, substructure, unique applications, and data acquisition and processing. Measurement techniques such as neutron diffraction and time-of-flight neutron diffraction, X-ray diffraction and EBSD, including EBSD coupled with XEDS are covered as well as a broad variety of processing techniques, such as rolling, wire drawing, hot temperature extrusion, and various techniques of severe plastic deformation. Readers will also find information on heat treatment and on epitaxial deposition of thin films. The materials studied are steel, aluminum composites, titanium alloys, magnesium alloys, and the currently widely studied multi-component alloys.

More details on the Special Section can be found here (including free access to selected articles).

Effect of Pulse Duration on Corrosion and Impression Creep Properties of AA5083‐H111 Al–Mg Alloy Weldments Processed by P‐GTAW

By Mustafa Umar and Paulraj Sathiya

The AA5083 Al-Mg alloy is mainly used in shipbuilding, automobile and aerospace industries. Welding of this alloy causes strength reduction and makes it susceptible to corrosion and creep failures. These issues can be minimized by modifying microstructural features of the weldment. Many investigators have gone for grain refinement in the fusion zone by varying welding parameters. So far, most of attempts have been made to study the effect of common parameters such as welding current, welding speed and pulse frequency. In the recent paper Mustafa Umar and Paulraj Sathiya from National Institute of Technology, Tiruchirappalli, India, first study the effect of pulse duration on corrosion and impression creep properties of AA5083-H111 Al-Mg alloy weldments processed by P-GTAW.

Dynamic Transformation Mechanism for Producing Ultrafine Grained Steels

By Lijia Zhao, Nokeun Park, Yanzhong Tian, Akinobu Shibata, Nobuhiro Tsuji

Dynamic transformation mechanisms for the production of ultrafine grained steels represent an important area in grain refinement strategies. Among the different grain refinement strategies, thermomechanical controlled processing employing dynamic transformation, that is, ferrite transformation during deformation of austenite, is considered as the simplest and commercially exploitable approach to produce ultrafine ferrite with grain size of a couple of microns or below.

Lijia Zhao and colleagues from the Colorado School of Mines, Golden, CO, USA, present a review that highlights the major trends in dynamic transformation and ultrafine ferrite formation.

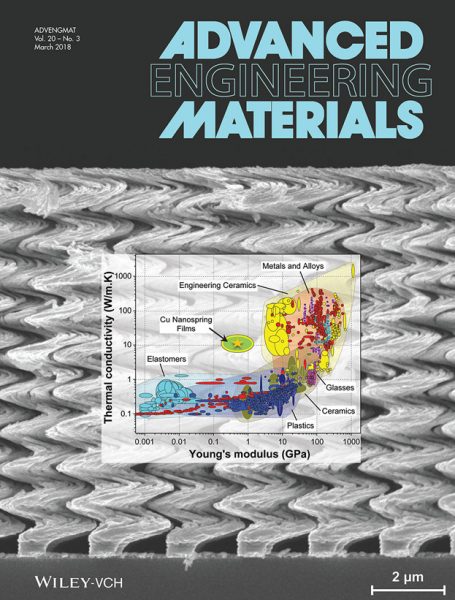

Cu Nanospring Films for Advanced Nanothermal Interfaces

By Dimitrios A. Antartis, Ryan N. Mott, Debashish Das, David Shaddock, Ioannis Chasiotis

Cu nanospring films can serve as an excellent thermal interface material, with roughly 500 times smaller stiffness than bulk Cu and 50–100 times higher thermal conductivity than polymeric materials with similar stiffness. In this study by Ioannis Chasiotis et al. from the University of Illinois at Urbana-Champaign, USA, present an advanced thermal interface material comprised of dense and orderly arrays of 10‐μm high Cu nanosprings with tunable normal and shear compliance and high thermal conductivity. The combination of mechanical and thermal properties makes it possible to populate the large empty space in the materials selection chart of thermal conductivity versus elastic modulus.

Unique Shape Memory Elastomer Associated with Reversible Sacrificial Hydrogen Bonds: Tough and Flexible When Below Its Tg

By Tengfei Lin, Siyuan Li, Jinhuang Ke, Yuying Zheng, Yan Yu

A new design strategy for fabricating elastomeric shape-memory polymers is explored by Tengfei Lin and co-workers from Fuzhou University, China, with the goal of achieving low-temperature flexibility and avoiding fragility and brittleness. Sacrificial and reversible hydrogen bonds are engineered into a cross-linked rubber network by introducing hindered phenol moieties into a zinc-diacrylate-cured epoxidized natural rubber.

The idea is that a great amount of mechanical energy can be dissipated via the dissociation of these sacrificial bonds, preserving in this way the covalent bonds in the polymer backbone and therefore adding strength and toughness to the material.

Tough and flexible shape memory elastomers are obtained with much improved properties. The sacrificial hydrogen bonds can be reversibly broken and re-formed, giving the elastomer its shape-memory properties. The hydrogen bonds can dissipate energy under external pressure and heat, facilitating the orientation of the rubber chains, and allowing the shape-memory polymers to regain their mobility and endure large deformations even below their glass transition temperatures.