You sit down for dinner at your favorite Persian restaurant. Your shargi arrives, and you allow yourself to be transported away by the rich aromas. You begin to dig into the dish when… CRACK… there goes a filling. The future suddenly constricts to contain little but a trip to the dentist.

A team from Sweden have been working toward designing stronger, more durable materials for tooth fillings and bone repair. They recently reported a set of new materials, made from ingredients that form strong cross-links when exposed to high energy visible light. The particularly high density of cross-links enabled by these mixtures, give the materials some impressive properties.

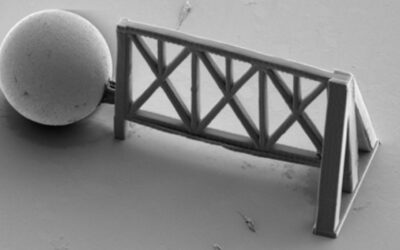

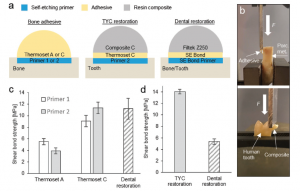

Test for material adhesion strength

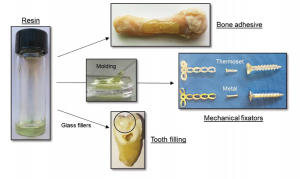

Before the mixture is cross-linked, it is readily mouldable (see below), allowing easy adaptation for individual patient requirements. The team tested the strength and toughness of their materials, as well as their ability to undergo deformation without rupture, finding results that matched or exceeded various commercial products. They then demonstrated that neither the individual ingredients nor leaching by the final product provoked cytotoxic effects.

From flexible to rigid

In a final experiment the strength of adhesion to bone and teeth was tested (see left). To help this test mimic physiological conditions, the bone and tooth were wrapped in wet tissue during the adhesion procedure, then immediately immersed in water. The new material was found to adhere much more strongly to the biological samples than an older technology.

Given these promising results, the team hopes that this technology might one day improve outcomes for patients, and provide the basis for further growth in the field of biocompatible resins.