Chemical modification – as a viable alternative to the synthesis of new polymers – is a very challenging area of polymer science and technology. It requires the combination of diverse areas of expertise, ranging from the basics of polymer chemistry, reaction kinetics, thermodynamics and rheology, to knowledge of compounding techniques and polymer processing operations.

Chemical modification – as a viable alternative to the synthesis of new polymers – is a very challenging area of polymer science and technology. It requires the combination of diverse areas of expertise, ranging from the basics of polymer chemistry, reaction kinetics, thermodynamics and rheology, to knowledge of compounding techniques and polymer processing operations.

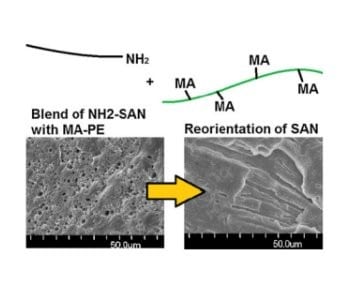

As a typical example, solvent-free reactive extrusion offers environmental benefits while also being economical because of the use of conventional processing equipment. Or, vulcanization as the most classical and well-known process allows the transformation of an unusable material into a product with impressive engineering properties, including resistance to heat, light, dimensional stability, mechanical strength, chemical and solvent resistance.

Entitled “Advances in Chemically Modified and Functionalized Polymers”, the recent special issue of Macromolecular Reaction Engineering was guest-edited by Marianna Kontopoulou (Queen’s University Kingston, Canada) and presents contributions from some of the top research groups working in the field.

It shows various techniques utilized to produce functionalized polymers, ranging from the production of ionomers and functionalized polypropylenes to surface modification of polymers, as well as relatively new applications in nanocomposites and biopolymers – demonstrating the true diversity and multidisciplinarity of this area.

Read here for free the full introductory Essay by Marianna Kontopoulou:

“Advances in Chemically Modified and Functionalized Polymers”