Polymers are the products of industrial processes and often tower-type multi-zone reactors are used to produce polymers. Innovations in reactor technologies can therefore lead to innovations in polymer products. In his recent work in Macromolecular Reaction Engineering, H. Tobita (University of Fukui, Japan) reveals that division of the zones in multi-zone reactors makes a significant difference in chain microstructure, such as molecular weight distribution, the distribution of branch points, and the radii of gyration of the product polymers.

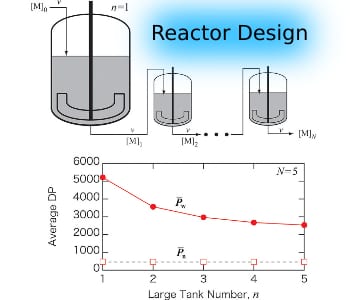

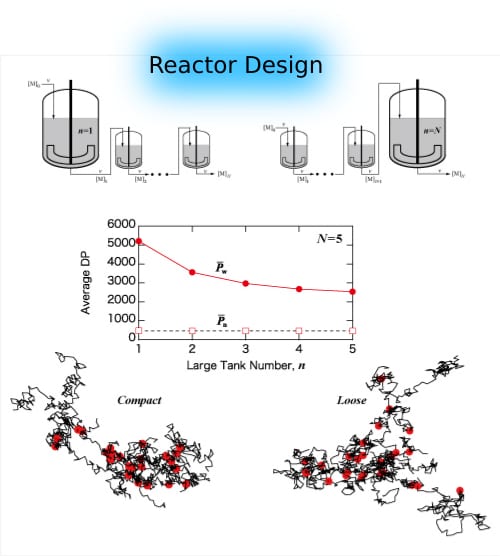

The article deals with conditions that can be found in high-pressure polymerization of ethylene to produce low-density polyethylene (LDPE): free-radical polymerization that involves chain transfers to the polymer, leading to both long-chain branching and chain scission. As a simplified model for a multi-zone type reactor, a series of continuous stirred-tank reactors (CSTRs), consisting of one big tank and the same N-1 small tanks, is considered theoretically. This reactor configuration allows keeping important properties like the final conversion, average densities of both branching and scission of the product polymers unchanged, irrespective of the tank arrangement. Also the residence time distribution of the whole series of reactors is not changed by the tank arrangement.

Now, what kind of tank order gives the largest weight-average molecular weight (Mw)?

It was found that the largest Mw is obtained for the big tank as the first reactor (case F), the smallest Mw were found when that big tank came last (case L). Case F leads to compact globular structure for highly branched polymers, while case L gives more random and loose structures. When the branched polymers having the same molecular weight (Mw) are compared, the branching density of case F is smaller than case L. However, because of the differences in branched structure (compact or loose), the relationship between the mean-square radius of gyration and Mw is essentially unchanged by the tank order.

With his theoretical calculations Tobita does not only improve the understanding of industrial polymerization processes but also provides a new way of thinking about innovation in reactor design that allows the production of branched polymer products with different grades by changing the location of division plates in tower-type multi-zone reactors.